Key Features

| High-quality construction |

| Excellent high-temperature resistance |

| Highly durable & flexible |

| Good chemical resistance |

| FDA & high-temperature grades available |

| Wide selection of colors |

| Bespoke manufacturing available |

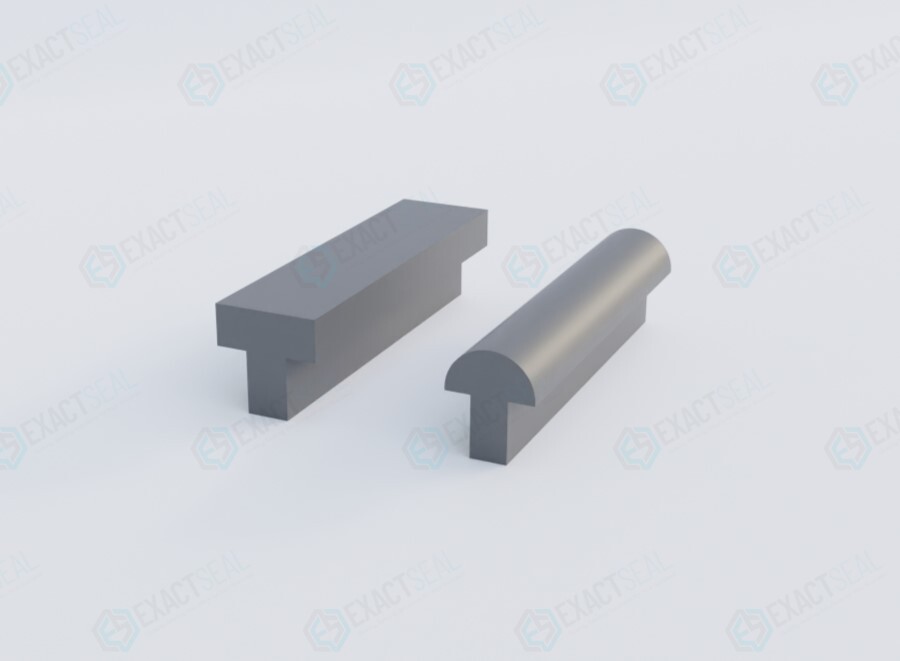

Manufacturing Excellence in U Channel Profiles

At Exactseal, we specialize in manufacturing high-quality U channel profiles that cater to a wide range of sealing and edge protection needs. Our extensive product line includes U channel rubber edge trim, clip-on U channels, and U channel weather stripping, each designed to provide superior sealing and protection for various applications. Utilizing advanced manufacturing techniques and premium materials like EPDM and silicone, our rubber profiles are engineered to meet the highest standards of durability and performance. Whether it’s a capping rubber seal or an extruded rubber U channel, we ensure our products deliver reliable and efficient solutions for our customers.

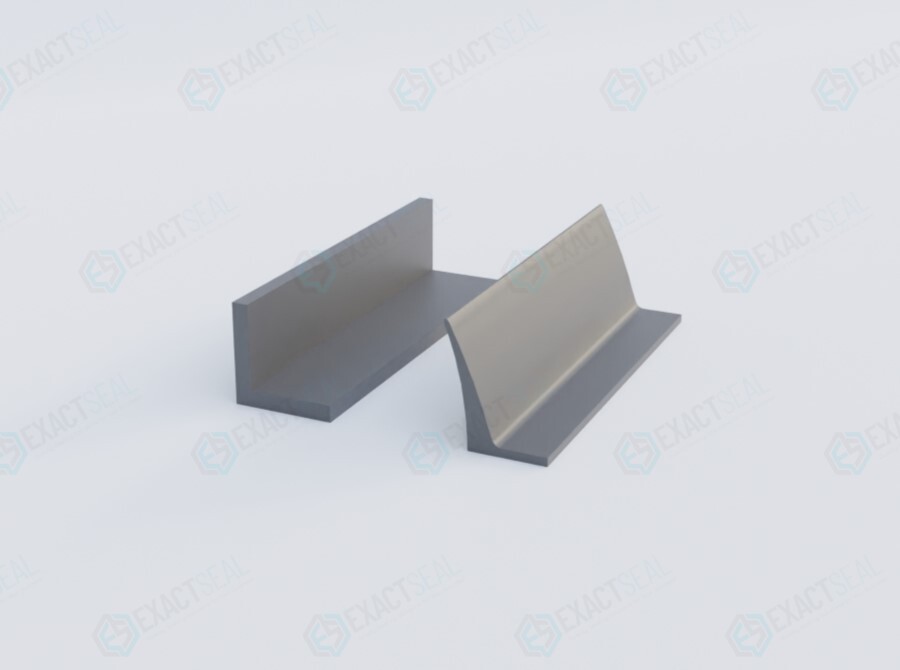

Versatility of U Channel Profile Across Industries

Our U channel profiles are incredibly versatile and find applications in numerous industries. Our products are used in various sectors, including automotive, construction, marine, and industrial. They protect edges, seal gaps, and enhance the longevity of various components. The EPDM U seals and EPDM U channels are particularly popular for their excellent weather resistance and durability. This makes them ideal for outdoor and harsh environment applications. Silicone U channel gaskets are perfect for high-temperature applications, providing a dependable seal in extreme conditions. The adaptability of our rubber profiles ensures they meet the diverse requirements of different industries.

Precision Engineering and Long-Lasting Performance

At Exactseal, we emphasize precision engineering and long-lasting performance in all our products. Our U channel profiles, including U channel rubber edge trim and clip-on U channels, are meticulously designed. This ensures a perfect fit and maximum sealing efficiency. Made from high-quality EPDM and silicone materials, our U channel profiles withstand various environmental stresses. These stresses include UV radiation, ozone, and extreme temperatures. This commitment to using premium materials ensures that our products maintain their integrity and functionality over time. As a result, they provide consistent, high-quality performance.

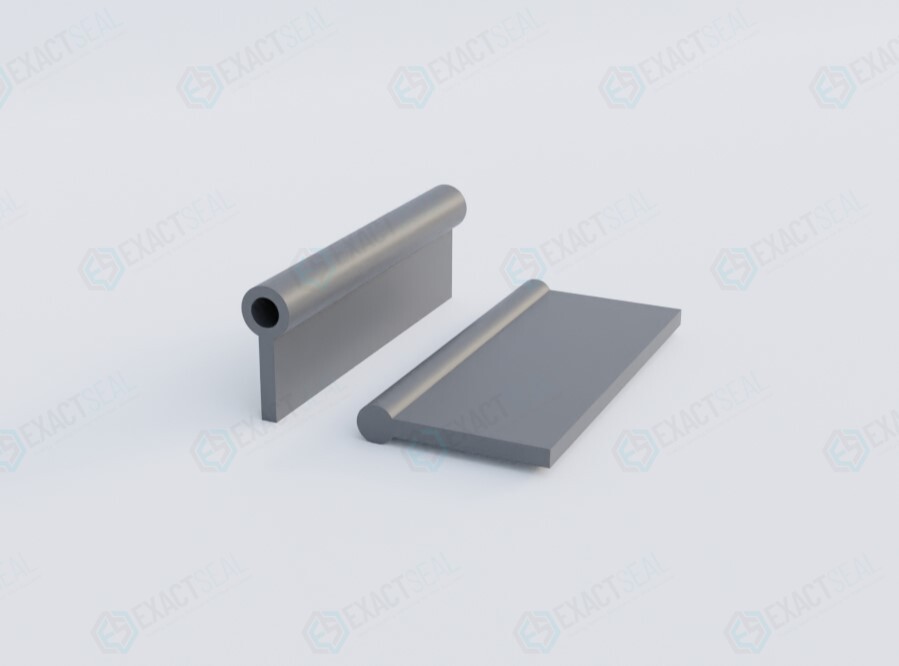

Bespoke Manufacturing Capabilities

Our bespoke manufacturing capabilities set us apart in the industry. We understand that each project has unique requirements, and we offer custom solutions tailored to meet specific needs. Whether it’s a particular size, shape, or material composition, our team of experienced engineers and technicians works closely with clients to develop custom U channel profiles, including EPDM U channels, silicone U channel gaskets, and more. Our flexible manufacturing processes and state-of-the-art equipment enable us to handle complex projects and deliver exceptional, customized sealing and edge protection solutions.

Unmatched Quality Standards

At Exactseal, quality is at the forefront of everything we do. We adhere to stringent quality control standards throughout the manufacturing process. This ensures that every U channel profile meets our rigorous benchmarks for excellence. Our dedication to quality, combined with our innovative approach and customer-focused service, makes us a trusted partner for sealing and edge protection solutions. Choose Exactseal for your U channel profile needs. Experience the difference in performance, durability, and reliability that our products provide. Trust us for all your capping rubber seal, U seal, and extruded rubber U channel requirements. See why we are the preferred choice for high-quality U channel profiles.

Specifications

| Application | Panel protection & gap sealing in various industries |

| Product | U Channel Profile |

| Hardness (Shore A) | 20° - 80° (depending on profile) |

| Material | Silicone, EPDM, Neoprene, Nitrile (Buna-N), FKM (Viton), FFKM (Kalrez), TPE, TPV |

| Colour | Wide variety of RAL numbers as standard |

Applications

| Aesthetic panel protection |

| Gap sealing |

| Food & beverage preparation |

| Medical & science industries |

| Electrical equipment protection |

| Aerospace industry |

| Interior & exterior applications |

Technical Information

| Properties | Values |

|---|---|

| Compound | Silicone |

| Hardness (Shore A) | 20° - 80° (depending on profile) |

| Temperature Resistance | Excellent high-temperature resistance |

| Flexibility | Highly durable & flexible |

| Chemical Resistance | Good chemical resistance |