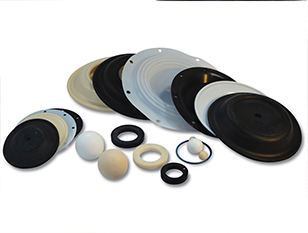

Rubber Diaphragms

At Exactseal, our commitment to precision engineering is exemplified in our comprehensive diaphragm manufacturing capabilities. This offers versatile solutions tailored to diverse industry needs. Our fabric-reinforced diaphragms bonded with metal inserts, seamlessly combine the flexibility of rubber with reinforced strength. Which provides enhanced durability for applications demanding increased tensile strength and resistance to wear and tear.

Leveraging the unique properties of Polytetrafluoroethylene (PTFE), our PTFE-coated diaphragms stand out for their exceptional chemical resistance and temperature stability. Making them well-suited for environments with aggressive chemicals and extreme temperatures and pressure. This ensures reliable performance in demanding applications.

The versatility of our diaphragm solutions extends to rolling diaphragms, designed for optimal flexibility and longevity. With applications spanning industries such as automotive, aerospace, and medical, our rolling diaphragms showcase efficient and reliable movement, making them suitable for dynamic systems.

Specifically engineered for precise control of fluid flow in pumps and valves, our pump and valve diaphragms are crafted with materials ensuring resilience, chemical resistance, and longevity. These diaphragms play a crucial role in fluid-handling systems, contributing to their efficiency and reliability. Our customers in different industry sectors and OEMs rely on us for their mission-critical Rubber diaphragm needs.

Applications of our Rubber Diaphragms :

- Pumps and valve manufacturers: leverage our fabric reinforced pump and valve diaphragms with metal inserts to act as seals in pumps and valves to regulate the flow, direction, and pressure of liquids and gases.

- Pharmaceutical manufacturers leverage these diaphragms to regulate the flow of fluid/API delivery during injectables and oral suspension manufacturing.

- Bulk material handling operations across industries leverage our Actuators to convert pneumatic or hydraulic pressure into mechanical movement in actuators while ensuring a consistent pressure differential between the media.

- Automotive industry: They are used in various automotive components, such as fuel injectors and vacuum pumps.

- Aerospace industry: They are used in aircraft and spacecraft components for various sealing and actuation purposes.

We have years of experience in manufacturing rubber diaphragms in all shapes and sizes, from tiny discs to sheets spanning meters. Furthermore, We manufacture them in different hardness durometers. Softer diaphragms with Shore A 40-50 Duro for delicate tasks. And harder ones with Shore A 65-80 Duro for high-pressure applications like in the case of oil refineries, gas pipes, or beverage bottling.

Diverse Range of Diaphragms

Common types of rubber diaphragms we manufacture to serve our customer and their diverse range of applications include:

- Flat Diaphragms: These workhorses are thin sheets, perfect for basic sealing and separating functions. Think check valves or pump membranes.

- Convoluted Diaphragms: Imagine an accordion made of rubber. These boast folds and bellows, increasing surface area and flexibility for pumping, metering, and regulating fluids.

- Dish-Shaped Diaphragms: Picture a shallow bowl. These diaphragm cup liquids, ideal for applications like dispensing or pressure relief valves.

- Rolling Diaphragms: Think of a top hat-shaped rubber diaphragm that combines the properties and function of both Bellows and Diaphragms. These diaphragms continuously move fluids or gases, often used in hygienic applications like food and pharmaceutical processing among others.

Materials we use to manufacture our diaphragms

We have proven expertise in manufacturing these diaphragms from a variety of rubber compounds while reinforcing them with a variety of meshes/fabrics like nylon, dacron, nomex, kevlar, cotton, and steel to name a few. In a quick summary, here are a select few materials that we use to manufacture our diaphragms for your reference to help select the ideal rubber compound based on your diaphragm operating condition:

- EPDM Diaphragms (Ethylene Propylene Diene Monomer): A champion against water, steam, and ozone, EPDM excels in outdoor and plumbing applications.

- Nitrile (NBR), FKM (Viton), FFKM (Kalrez) Diaphragms: Oil and fuel are no match for these elastomers, making them a go-to for automotive and industrial pumps. While FDA compounds of these rubbers are used widely in Pharmaceutical applications for their chemical-resistant properties.

- Silicone Diaphragms (Including USP Class VI diaphragms): Biocompatible and heat-resistant, silicone is an ideal choice of material in medical devices and food processing equipment.

- Neoprene Diaphragms: Weatherproof and abrasion-resistant, neoprene tackles harsh environments like construction and mining.

Exactseal serves a diverse range of industries with our comprehensive diaphragm solutions. We provide reliable components that meet or exceed industry standards. Whether you need rolling diaphragms, pump and valve diaphragms, Viton diaphragms, EPDM diaphragms, silicone diaphragms, USP Class VI diaphragms, neoprene diaphragms, or any other type of rubber diaphragms, we have the solution for you. Moreover, we tailor our products to meet your specific requirements for shape, size, and materials. In addition to our diaphragm offerings, we provide a broad spectrum of rubber solutions, including custom rubber extrusion, molded parts, tubing, hoses, O-rings, gaskets, seals, and inflatable seals. Our commitment to quality, versatility, and customization makes us a trusted partner for manufacturing excellence in rubber products.