Die Cut Gaskets (Flat/CNC Knife Cut)

Key Features

| High Volume Production |

| Precision Cutting Process |

| Versatile Material Usage |

| Excellent Sealants |

| Low Tolerance |

| Wide Industry Application |

| Customizable Fabrication Methods |

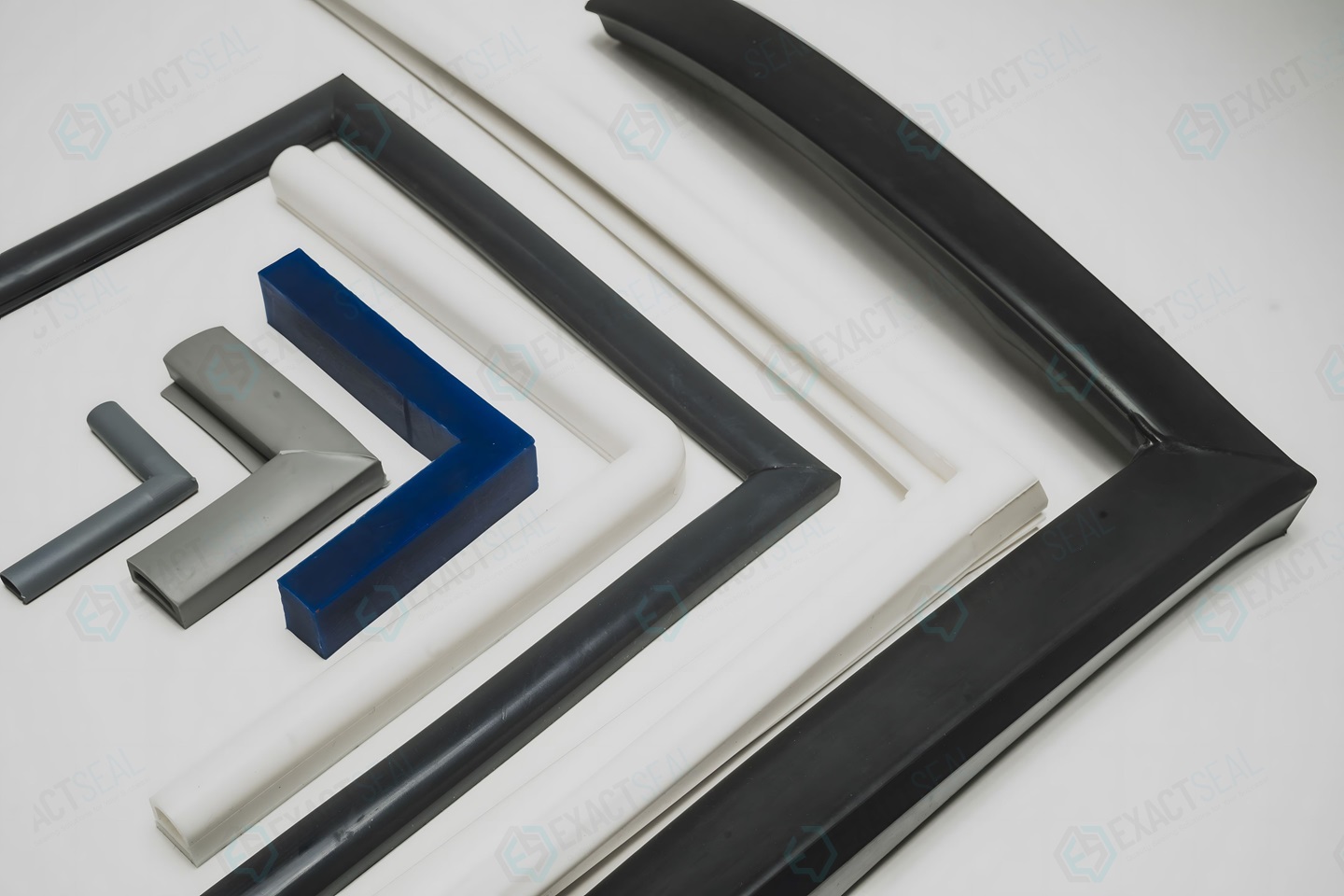

Exactseal offers high-quality Die Cut Gaskets, also known as Flat Gasket, CNC Knife Cut or Flange gaskets, designed to provide precise and reliable sealing in a wide range of applications. We manufacture our die cut gaskets using advanced die-cutting or CNC knife cutting techniques. This ensures precise dimensions, tight tolerances, and consistent performance. This process employs sharp, slender blades, known as dies, to carve out different shapes from various materials. We predominantly make our gaskets ring-shaped from materials like rubber, which allows for cutting before assembly. Many professionals trust our gaskets, which have exceptional sealing properties and durability, in industries such as automotive, aerospace, and manufacturing for various sealing applications.

The die-cutting process involves a steel rule die, a steel strip bent to the profile of the part being cut. A plywood or phenolic board embeds this die, holding it in shape. The steel knife’s exposed edge is sharpened to cut through the material with precision.

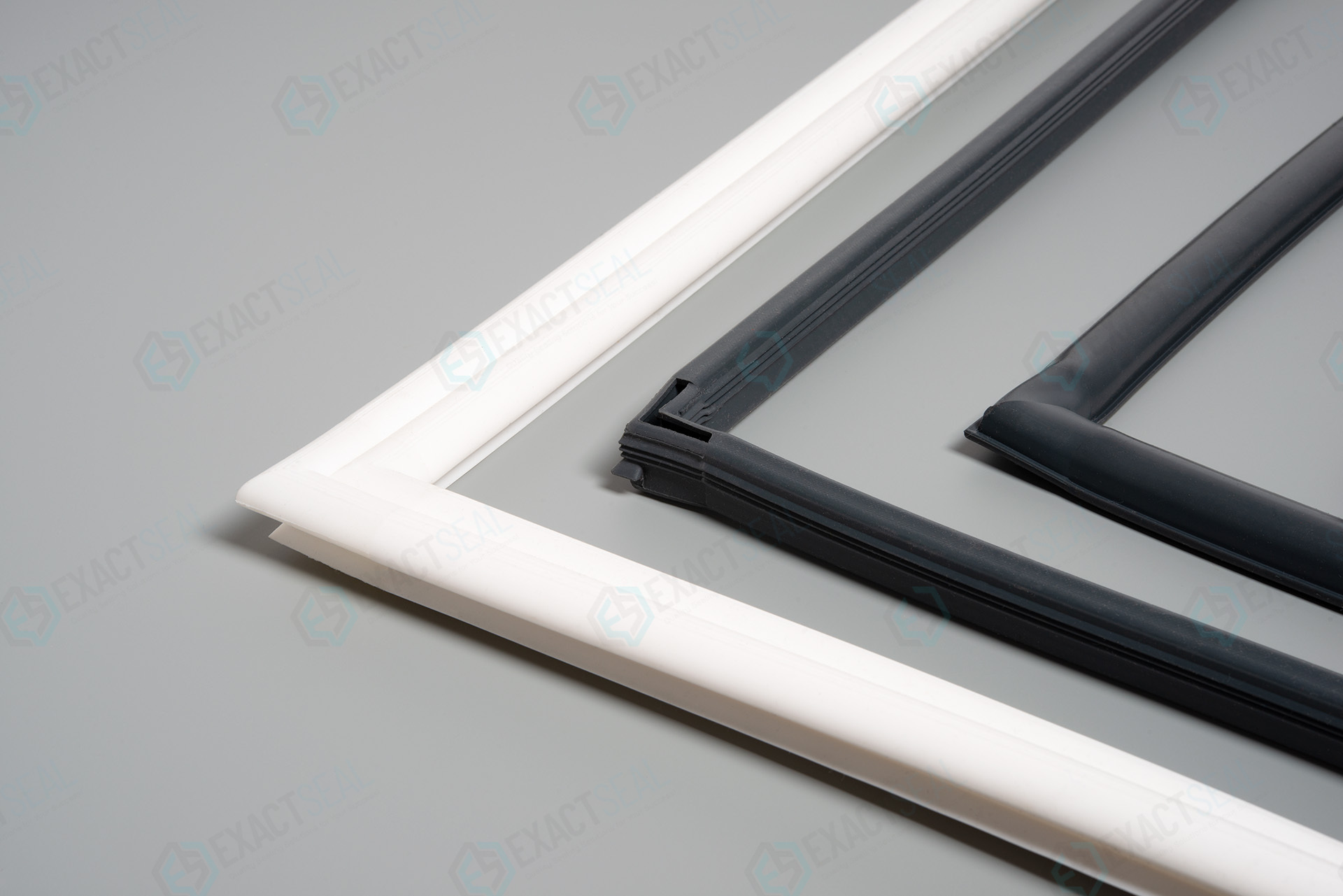

Flat Gaskets (Die/CNC Knife Cut): Precision Solutions for Sealing Applications

Flat gaskets play a crucial role in sealing flanged connections in pipelines, machinery, and equipment. Our flange gaskets are available in a variety of materials, including rubber, silicone, and EPDM, to suit different sealing requirements and environmental conditions. Additionally, our gaskets provide reliable sealing performance for sealing flanges in automotive engines, industrial pumps, or HVAC systems, ensuring the integrity and efficiency of the system.

Rubber Jar Gaskets: Ensuring Airtight Seals for Food Preservation

Rubber jar gaskets play a crucial role in food preservation. They provide a secure and airtight seal for jars and containers. Whether it’s storing homemade jams, pickles, or sauces, rubber jar gaskets effectively seal the lids of jars. They prevent air and moisture from entering and spoiling the contents. The flexibility and resilience of rubber make it ideal for creating tight seals. Therefore, these can withstand the rigors of everyday use. Exactseal’s rubber jar gaskets are designed to fit various jar sizes and shapes. This ensures a snug fit and reliable sealing performance. Additionally, with our high-quality rubber materials and precision manufacturing processes, our jar gaskets help consumers preserve the freshness and flavor of their homemade goods with confidence.

Precision Die-Cut Gaskets for Tight Sealing

Exactseal’s die-cut gaskets are manufactured with precision using advanced die-cutting equipment. This ensures accurate dimensions and tight tolerances. The precision manufacturing process allows us to produce gaskets with intricate shapes and configurations to meet specific sealing requirements. Our Die Cut Gaskets serve as excellent sealants. Industries prefer them for their precision and low tolerance, and they use them across various applications. These include LED gaskets, NEMA and UL 50 enclosure gaskets, battery pads, radome gaskets, environmental gaskets, and EMI gaskets. Whether you need circular, square, or custom-shaped gaskets, our die-cutting capabilities ensure that each gasket fits perfectly. It seals effectively, reducing the risk of leaks and downtime.

Customized Solutions for Your Sealing Needs

We understand that each sealing application has unique requirements. That’s why we offer customized die cut gasket or flat gasket solutions to meet specific needs. Our team works closely with customers to provide gaskets for standard flange connections or custom-designed ones for specialized applications. These address their specific sealing challenges. In addition to that, with our expertise in material selection, design optimization, and manufacturing techniques, we can create flat gaskets that meet your exact specifications and performance requirements. In addition to die cutting, we at Exactseal also offer flash cutting, waterjet cutting, and custom molding. The best gasket fabrication method varies depending on tolerances, quantities, and the materials being cut.

Why Choose Exactseal for Die Cut Gaskets?

Precision Manufacturing: Our die cut gaskets are manufactured with precision using advanced die-cutting or CNC knife cutting techniques, ensuring accurate dimensions and tight tolerances.

Versatile Materials: We offer flat gaskets in a variety of materials, including rubber, silicone, and EPDM, to suit different sealing requirements and environmental conditions.

Customization Options: We offer customized solutions to meet specific application requirements, including custom shapes, sizes, and materials.

Expertise: With years of experience in gasket manufacturing, our team provides expert advice and support to help you find the right sealing solution for your specific application needs.

Specifications

| Application | Industrial, Automotive, Aerospace, Medical |

| Product Name | Flat Gasket |

| Hardness (Shore A) | 70 (This can vary based on material) |

| Material | Silicone, EPDM, Nitrile (Buna-N), FKM (Viton), Neoprene, TPE, TPV (Santoprene), HNBR, SBR, PTFE (Teflon), FFKM (Kalrez), Natural Rubber |

| Colour | Black, White, Red, etc. (Can vary based on material) |

Applications

| Sealing connections for industrial pipelines |

| Creating detachable connections for housings |

| Preventing media escape in manufacturing |

| Compensating for surface unevenness |

| Ensuring tight seals in engines |

| Maintaining integrity in machinery joints |

Technical Information

| Property | Value |

|---|---|

| Material | Silicone, Fluorosilicone, EPDM, Butyl (Buna-N), Neoprene, SBR, FKM/Viton, PTFE |

| Hardness (Shore A) | 70 (This can vary based on material) |

| Temperature Resistance | Varies based on material |

| Pressure Resistance | Varies based on material |

| Chemical Resistance | Must be resistant to the media being sealed |

| Compressibility | Must be deformable to adapt to the unevenness of the sealing surface |