Key Features

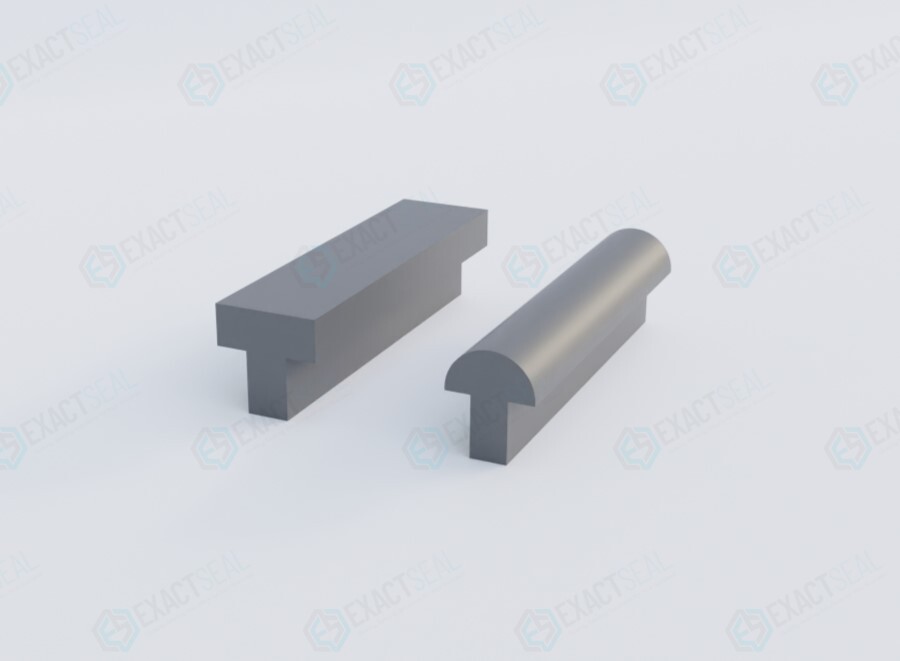

| Flexible Bulb Shape |

| Weather Resistance |

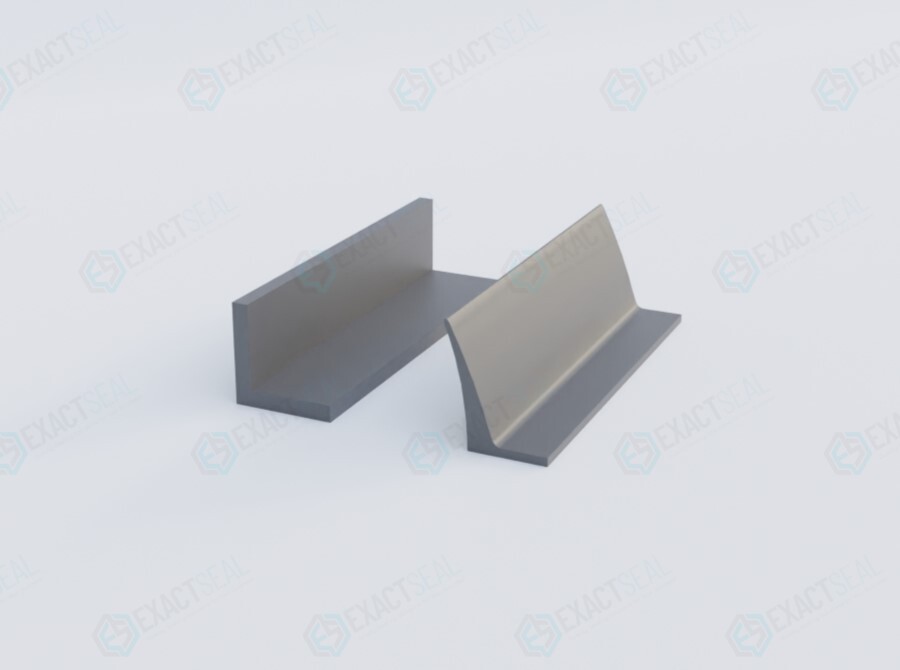

| Versatile Applications |

| Material Resilience |

| Conformance to Surfaces |

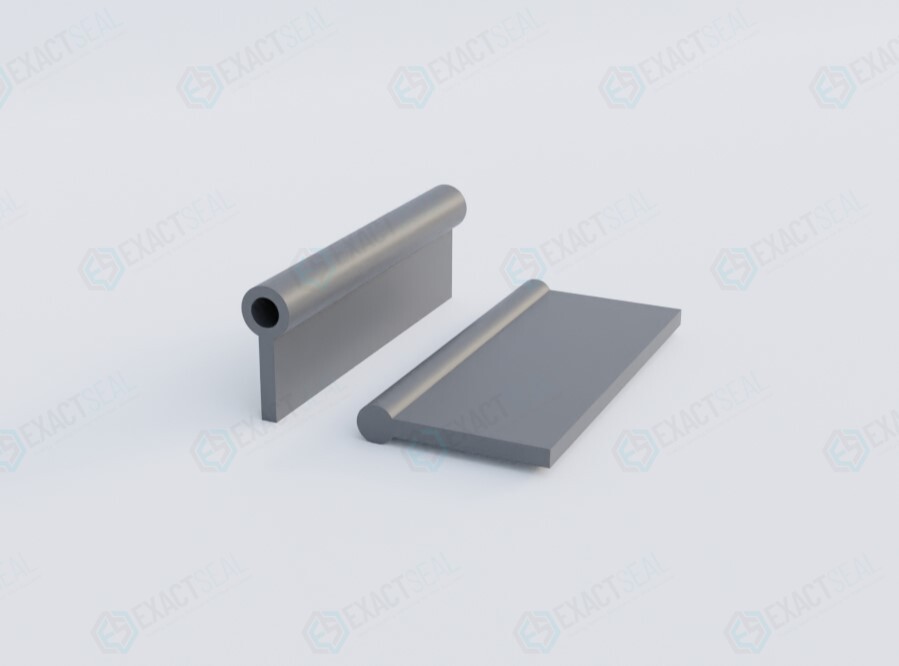

| Secure Fit |

| Longevity |

At Exactseal, we pride ourselves on being industry leaders in the manufacturing of custom rubber extrusions, including our renowned bulb seal profiles. These profiles are also known as Rubber Bulb Seal Gasket, Bulb Seal Gasket, and Bulb Shaped Rubber Profiles. From Material’s perspective, these are also known as EPDM Bulb Seal, Neoprene Bulb Seal, Silicone Bulb Seal and more. With state-of-the-art facilities and a team of experienced professionals, we specialize in producing high-quality rubber bulb seal profiles tailored to meet the diverse needs of our clients. Our commitment to innovation and continuous improvement drives us to deliver cutting-edge solutions that set the standard for excellence in the industry.

Versatility Across Industries: The Application of Bulb Seal Profile

Our bulb seal profiles find extensive use across various industries, showcasing their remarkable versatility and adaptability. From automotive and aerospace to construction and manufacturing, our sealing solutions play a crucial role in preventing leaks, controlling vibration, and enhancing overall product performance. Moreover, with their ability to withstand extreme conditions and maintain consistent sealing integrity, our bulb seal gaskets are trusted by industry leaders worldwide for their reliability and effectiveness.

Precision Engineering for Lasting Performance

At Exactseal, we understand the importance of precision engineering in ensuring the longevity and effectiveness of our products. We engineer our rubber bulb seal profiles with meticulous attention to detail. Additionally, we utilize advanced materials and manufacturing techniques to achieve optimal sealing performance. We design each profile to withstand harsh environmental conditions, extreme temperatures, and rigorous usage. With this we are guaranteeing long-lasting durability and reliability in every application. Our dedication to precision engineering ensures that every rubber bulb seal profile meets the highest standards of quality and performance.

Bespoke Manufacturing Capabilities: Tailored Solutions for Every Need

One of the hallmarks of Exactseal is our ability to provide bespoke manufacturing solutions. With this we meet the unique requirements of our clients. Our team is dedicated to delivering tailor-made solutions that exceed your expectations. Whether you need a custom profile design, specific material properties, or precise dimensional tolerances. With our flexible manufacturing processes and personalized approach, we ensure that we produce every profile perfectly suited to its intended application. Additionally, we are providing maximum sealing effectiveness and performance. Our bespoke manufacturing capabilities empower our clients to achieve their unique sealing objectives with confidence and precision. We manufacture all our profile in various materials like EPDM Bulb seal, Neoprene Bulb Seal, Silicone Bulb Seal, Nitrile Bulb Seal and more.

Uncompromising Quality Standards: Why Choose Exactseal?

At Exactseal, quality is our top priority. We adhere to stringent quality control measures throughout the manufacturing process to maintain the highest standards of excellence. From raw material inspection to final product testing, we meticulously monitor every step. Our rubber bulb seal gaskets meet or exceed industry standards for performance, reliability, and durability. Moreover, with our commitment to quality craftsmanship, exceptional engineering expertise, and unmatched customer service, Exactseal is the trusted partner you can rely on for all your rubber extrusion needs. With our relentless pursuit of quality excellence ensures that every bulb seal profile we deliver offers uncompromising reliability and performance.

Specifications

| Application | Doors, windows, and enclosures, ensuring a secure and weather-resistant seal against dust, moisture, and noise |

| Product | Bulb Seal Profile |

| Hardness (Shore A) | 50-70 |

| Material | Silicone, EPDM, Neoprene, Nitrile (Buna-N), FKM (Viton), FFKM (Kalrez), TPE, TPV |

| Colour | Black |

Applications

| Enhances weather resistance and insulation in doors and windows. |

| Seals doors, windows, trunks, and compartments in automotive and marine applications. |

| Creates a secure, weatherproof seal for enclosures, cabinets, and panels. |

| Prevents the entry of dust, water, and contaminants in containers and storage units. |

| Improves energy efficiency by sealing access points in HVAC systems. |

| Safeguards internal components in electronic devices, appliances, and machinery. |

| Provides weather resistance and insulation for various outdoor equipment. |

Technical Information

| Propeties | Values |

|---|---|

| Compound | EPDM, Silicone, Neoprene |

| Hardness (Shore A) | 50-70 |

| Temperature Resistance | Wide range, material-dependent |

| Weather Resistance | Protects against elements |

| Compression/Flexibility | Bulb shape for flexibility and conformity |

| Chemical Resistance | Material-dependent, may resist certain substances |

| Sound Insulation | Provides sound insulation |