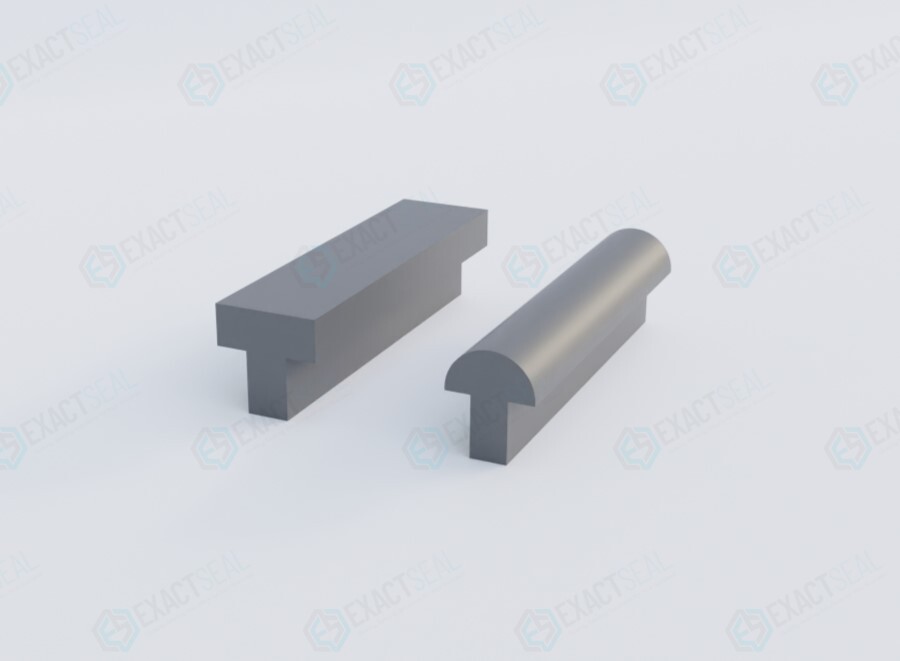

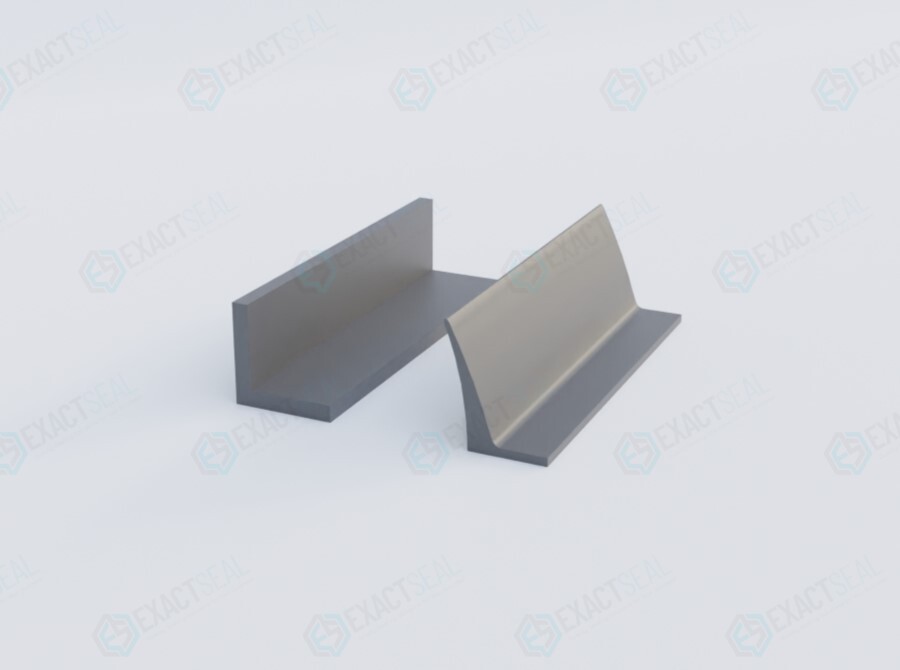

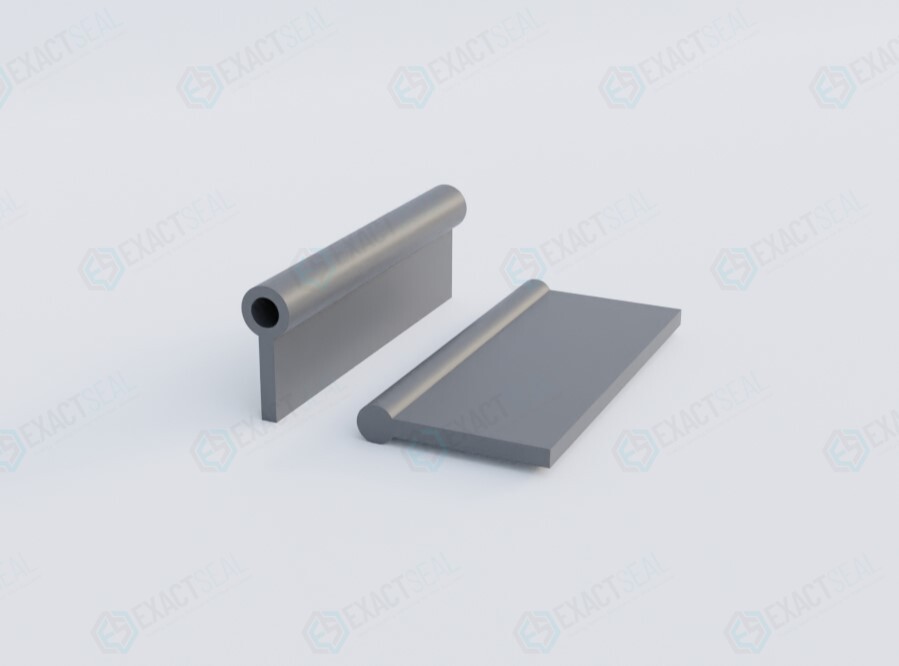

C Channel Profile

Key Features

| C-Shape for Easy Sealing Installation |

| Flexible Rubber Conforms to Surfaces |

| Resilient Material Maintains Seal Integrity |

| Versatile Applications in Various Industries |

| Material Variety for Diverse Requirements |

| Swift Installation in Manufacturing Processes |

| Protects Edges from Wear and Impact |

C Channel Profile also known as C Channel Gasket or C Channel Rubber is a cutting-edge solution in rubber extrusions and moldings, distinguished by its unique C-shaped cross-section. Meticulously engineered for sealing and protective purposes across a spectrum of industries including automotive, construction, and manufacturing, these profiles stand out for their user-friendly design, allowing for easy installation by effortlessly sliding onto edges or surfaces. Achieve your vehicle’s durability and performance with our premium rubber C-channel trim, expertly crafted to withstand various environmental conditions. Our fuel tank strap rubber ensures secure and reliable fastening, providing optimal protection and support for your vehicle’s fuel system.

C-Channel Rubber Trim: Unmatched Durability and Performance

Get the unparalleled advantages of our rubber C-channel trim, featuring a distinctive C-shaped configuration. Engineered for a secure seal, it maximizes the inherent flexibility and resilience of rubber, promising not only tight sealing but also effective vibration dampening and robust protection against a myriad of environmental elements. Additionally, from its innovative design to its exceptional performance, our C-channel rubber trim sets the standard for durability and reliability in automotive applications.

C-Channel Profile Crafted with versatile materials

Discover the epitome of adaptability in our C Channel Profiles. We craft our rubber profiles from an extensive selection of materials including EPDM, neoprene, silicone, and more. Each profile is meticulously tailored to meet specific application requirements, ensuring optimal performance and longevity. We focus on attributes like temperature resilience and chemical resistance. With this, our profiles offer durability and reliability across a spectrum of environmental conditions. From automotive to industrial applications, trust in the versatility and precision engineering of our C Channel gasket to deliver outstanding results every time.

We Manufacture Customised Rubber Profiles

Choose C Channel Profiles for reliable, top-notch solutions in sealing and protective applications. Count on our commitment to superior design and material performance for guaranteed satisfaction and dependability. Additionally, leverage our expertise in custom rubber extrusion manufacturing to tailor profiles precisely to your unique specifications. Which Ensures optimal performance and a perfect fit for your application needs.

Specifications

| Application | Sealing, edge protection, and vibration dampening in various industrial applications, including automotive, construction, and manufacturing. |

| Product | C-Channel Profiles |

| Hardness (Shore A) | 50-70 |

| Material Options | Silicone, EPDM, Neoprene, Nitrile (Buna-N), FKM (Viton), FFKM (Kalrez), TPE, TPV |

| Colour | Black |

Applications

| Automotive Seals: Seals doors, windows, hoods, and trunks in vehicles. |

| Construction: Weather stripping for windows and doors, providing insulation. |

| Machinery and Equipment: Protects edges, creates a barrier against contaminants, reduces vibration. |

| Electronics: Provides edge protection on electronic enclosures, seals sensitive components. |

| Marine Applications: Resists water and weathering, seals boat hatches and windows. |

| Industrial Equipment: Shields and seals edges on conveyors, machinery, preventing wear. |

| Aerospace: Ensures durability, sealing, and protection on aircraft components. |

| HVAC Systems: Serves as gaskets and seals, preventing air and moisture. |

| Medical Equipment: Utilized for sealing and protecting edges on medical devices. |

| Renewable Energy: Seals and protects components in solar panels, wind turbines. |

Technical Information

| Properties | Values |

|---|---|

| Compound | TPE / Silicone / EPDM / Neoprene |

| Minimum Temperature | -40°C / -50°C / -40°C / -6°C |

| Maximum Temperature | +250°C / +300°C / +93°C / +93°C |

| Compression Set Resistance | Excellent / Superior / High / High |

| Chemical Resistance | Moderate / Excellent / High / High |

| UV Resistance | Excellent / Exceptional / High / High |

| Tensile Strength | Good / Superior / Excellent / High |