Silicone Tubing and Hose

Key Features

| High Temperature Resistance |

| Excellent Flexibility |

| UV and Ozone Resistant |

| Non-Toxic for Food Applications |

| Resistant to Compression Set |

| Durable in Harsh Conditions |

| Versatile Across Industries |

Exactseal offers a comprehensive range of silicone tubing & hose solutions designed to meet the diverse needs of our customers. Our silicone hoses or silicone tubing are crafted with precision and expertise, utilizing high-quality silicone rubber materials to ensure exceptional performance, durability, and reliability in various applications. Whether your need is in automotive, industrial, or medical applications, our silicone tubing & hoses provide reliable performance under extreme conditions. From silicone vacuum hoses to high temp silicone hoses, our wide range of options caters to different temperature ranges and operating environments.

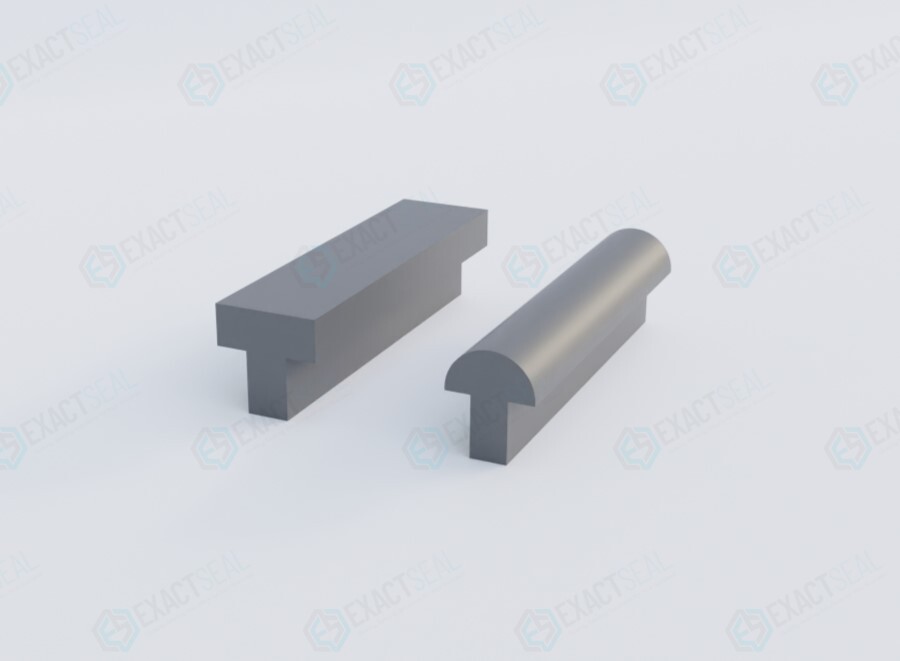

Silicone Rubber Tubing: Flexible and Resilient

Exactseal designs silicone rubber tubing to offer excellent flexibility and resilience. It’s suitable for a wide range of fluid transfer and medical applications. With its smooth bore and non-reactive properties, our silicone rubber tubing ensures the safe and efficient transfer of liquids and gases. Additionally, our tubing solutions are available in various sizes and configurations, including 1/4 silicone tubing. This is to meet the specific needs of different industries and applications. We are also open to manufacture custom silicone hoses as per your requirements.

High Temp Silicone Hose: Withstanding Extreme Temperatures

Our high temp silicone hoses are specially formulated to withstand temperatures ranging from -60°C to 220°C (-76°F to 428°F), making them perfect for applications where extreme heat resistance is required. Whether it’s automotive engine compartments or industrial machinery, our high temp silicone hoses deliver consistent performance even in the most demanding environments. In Addition, with their superior heat resistance and durability, our silicone hoses ensure reliable operation under high temperature conditions. We also manufacture vacuum hose for industries which offer exceptional durability and reliability, ensuring optimal performance in various applications.

Platinum Cured Silicone Hose: Purity and Biocompatibility

Exactseal’s platinum cured silicone hoses offer superior purity and biocompatibility, making them suitable for medical, pharmaceutical, and food processing applications. Manufactured using platinum curing technology, these hoses are free from peroxide by-products. Moreover, our silicone hose ensures the highest level of product integrity and safety. Our platinum cured silicone hoses provide reliable performance and durability. They are ideal for critical applications where purity and cleanliness are paramount.

Custom Manufacturing: Tailored Solutions for Unique Requirements

At Exactseal, we understand that every application is unique. That’s why we offer custom silicone hose solutions tailored to meet your specific requirements. Whether you need a particular size, shape, color, or material formulation, our team of experts can develop a customized solution that meets your exact specifications. From 3/8 silicone hoses to custom length silicone tubing, we work closely with you. This ensures that our silicone hose solutions meet your needs and exceed your expectations.

Why Choose Exactseal?

Premium Quality: Our silicone tubing and hoses are manufactured to the highest quality standards. This ensures exceptional performance and reliability in every application.

Wide Range of Options: With a comprehensive range of silicone tubing and hoses available, we offer solutions for a wide range of industries and applications.

Customization: We offer custom silicone hose solutions tailored to meet your specific requirements, ensuring a perfect fit for your application.

Technical Expertise: With years of experience in silicone rubber extrusion, our team has the knowledge and expertise to provide expert advice and guidance to help you find the right solution for your needs.

Specifications

| Application | Pharmaceutical, Biotechnology, Laboratories, Food Industries |

| Product Name | Silicone Tubing & Hose |

| Hardness (Shore A) | 50 ±5 |

| Material | 3-A Sanitary Grade Silicone, Food & Medical Grade (FDA 21, CFR177.2600 compliant), FDA Grade Closed Cell Silicone Sponge, NSF/ANSI 51 Approved, USP CL-VI Approved, UL-94 Compliant Silicone, Fire Retardant Silicone, Weather Resistant Silicone, X-Ray detectable, Thermally Conductive Silicone (Glass loaded), Electrically Conductive Silicone (Carbon loaded), Mil-Spec AA 59588, Petrochemical Resistant Fluorosilicone |

| Colour | Translucent or Customized |

Applications

| Coolant Transfer in Automotive Engines |

| Fluid Handling in Food Industries |

| Medical Equipment Manufacturing |

| Pharmaceutical Processing Equipment |

| High-Temperature Industrial Applications |

| Chemical Resistant Tubing in Laboratories |

Technical Information

| Property | Value |

|---|---|

| Material | Silicone |

| Temperature Range | -65°F to +400°F |

| UV and Ozone Resistant | Yes |

| Hardness (Shore A) | 50 ±5 |

| Tensile Strength | 1444 psi (9.96 MPa) |

| Elongation at Break | 608% |

| Modulus (Elasticity) at 100% | 186 psi (1.28 MPa) |

| Brittle Temperature | -100°F (-73.3°C) |

| Maximum Operating Temperature (Non-NSF Applications) | 500°F (260°C) |

| Maximum Operating Temperature (NSF Applications) | 350°F (176.7°C) |

| Compression Set (22 hours at 177°F, 80.6°C) | 35% |

| Tear Resistance (Tear Strength), Die B | 125 pounds per inch |