Spliced and Vulcanized Gaskets & O-Rings

Key Features

| High Temperature Resistance |

| Superior Pressure Tolerance |

| Strong Molecular Bond |

| Durable and Reliable |

| Customizable Shapes and Sizes |

| Cost-Effective Manufacturing |

| Ideal for Various Industries |

Spliced and vulcanized gaskets represent the pinnacle of precision engineering in sealing solutions. Spliced & Vulcanized gaskets can be the right solution for static applications. Crafted from high-quality materials and subjected to advanced manufacturing processes, these gaskets offer unparalleled resilience, durability, and sealing performance. They excel across a wide spectrum of applications. At Exactseal, we specialize in providing customized spliced and vulcanized gaskets tailored to meet the exact requirements of our discerning customers.

Advanced Vulcanization Process

Our spliced and vulcanized gaskets undergo a meticulous manufacturing process that involves precision splicing and vulcanization. During vulcanization, the gasket materials are exposed to heat and pressure, resulting in a permanent bond between the splice points. This advanced bonding technique ensures superior strength and durability. This allows the gaskets to withstand extreme temperatures, pressures, and environmental conditions without compromising their sealing integrity.

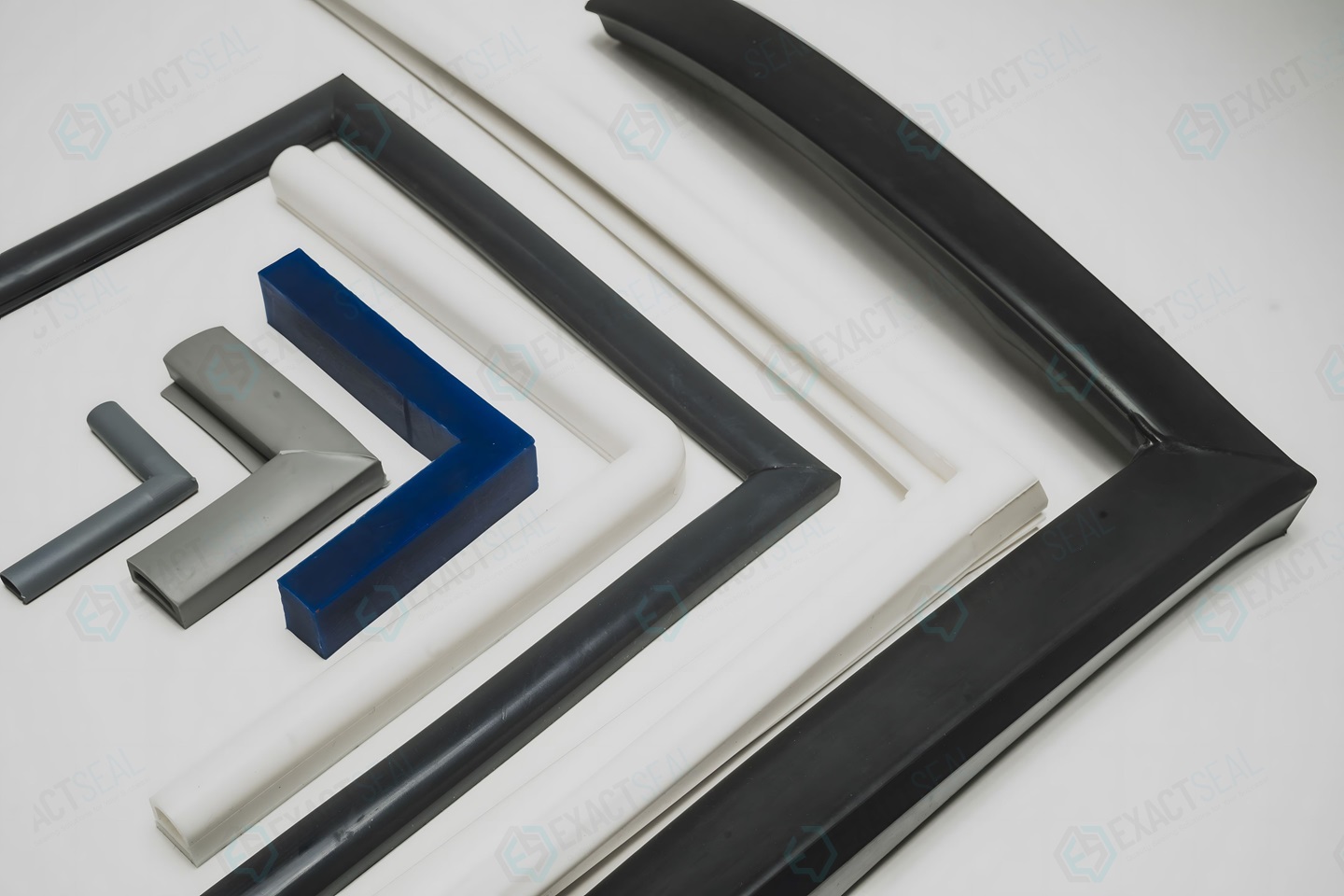

Custom Extruded Vulcanized Gaskets

Exactseal offers custom extruded spliced gaskets designed to fit the unique specifications of each application. Whether you require gaskets with complex profiles or precise dimensions, our team of experienced engineers can develop tailored solutions to meet your exact sealing needs. Additionally, if you need specific material properties, we can accommodate those requirements as well. With our state-of-the-art extrusion capabilities, we can produce gaskets in a variety of shapes, sizes, and materials. Additionally, our splicing capabilities ensure optimal performance and reliability in any application.

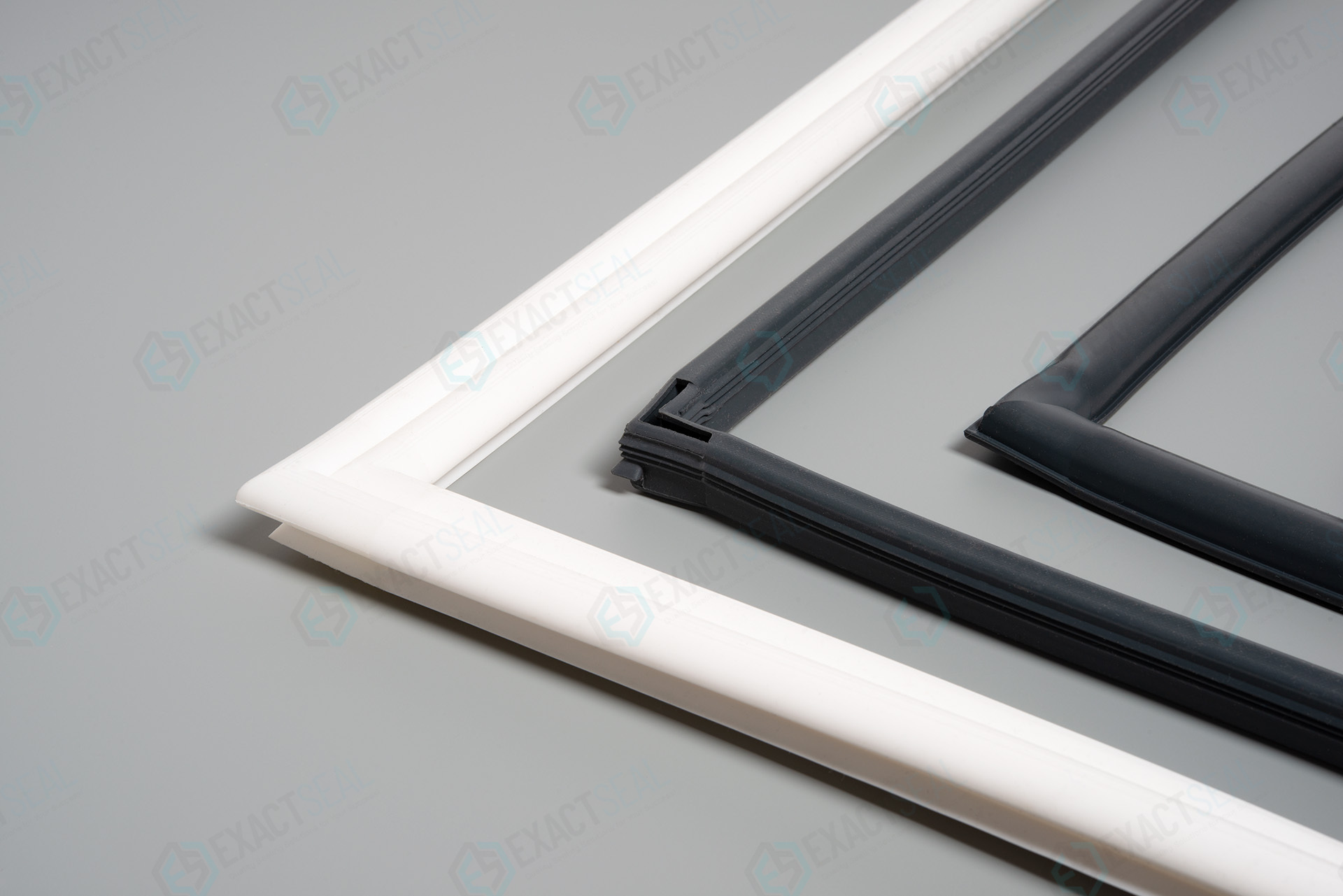

Superior Sealing Performance

Spliced and vulcanized gaskets deliver superior sealing performance in a wide range of industries and applications. The precise splicing technique ensures uniformity and consistency in the gasket profile, minimizing the risk of leaks or failures. Additionally, the vulcanization process enhances the gaskets’ resistance to compression set, allowing them to maintain their sealing properties over extended periods of use. Whether used in automotive, aerospace, industrial, or marine applications, spliced and vulcanized gaskets provide reliable sealing solutions that stand the test of time.

Spliced & Vulcanized O-Rings

Our spliced and vulcanized O-rings offer versatile and reliable sealing solutions for various applications. Spliced O-rings are crafted by cutting and joining lengths of O-ring cord, allowing for custom sizes and quick production, making them ideal for prototypes and non-standard dimensions. Vulcanized O-rings, on the other hand, undergo a heat and pressure curing process. With this process, we achieve a bond that is as strong as the original material. This process ensures superior durability, strength, and resistance to stress, heat, and chemicals, making vulcanized O-rings suitable for demanding environments. Additionally, our bonded O-rings provide robust seals for high-pressure applications, ensuring optimal performance and reliability. These O-rings feature a metal outer ring and a rubber inner ring, making them ideal for use as bolt seals in hydraulic equipment.

Why Choose Exactseal for Spliced & Vulcanized Gaskets?

Customization Options: We offer a comprehensive range of customization options for spliced and vulcanized gaskets. Which allows you to tailor the gaskets to your specific application requirements.

Advanced Manufacturing Processes: Our gaskets undergo advanced manufacturing processes, including precision splicing and vulcanization. Which ensures superior strength, durability, and sealing performance.

Exceptional Quality: At Exactseal, we commit to delivering gaskets of the highest quality, enforcing stringent quality control measures, and adhering to industry-leading standards.

Expertise: With decades of experience in the sealing industry, our team of engineers possesses the knowledge and expertise to provide reliable sealing solutions. This holds true even for the most challenging applications.

Specifications

| Application | Industrial, Automotive, Aerospace |

| Product Name | Spliced & Vulcanized Gaskets |

| Hardness (Shore A) | 70 |

| Material | Silicone, EPDM, Nitrile (Buna-N), FKM (Viton), Neoprene, TPE, TPV (Santoprene), HNBR, SBR, PTFE (Teflon), FFKM (Kalrez), Natural Rubber |

| Colour | Varies based on material |

Applications

| Sealing in Automotive Engines |

| Aerospace Equipment Leak Prevention |

| Industrial Machinery Vibration Damping |

| Fluid Systems in Pharmaceuticals |

| High-Pressure Pipe Sealing |

| HVAC System Component Sealing |

Technical Information

| Property | Value |

|---|---|

| Material | Nitrile Rubber |

| Hardness (Shore A) | 70 |

| Operating Temperature Range | -30°C to 100°C |

| Tensile Strength | 14 MPa |

| Elongation at Break | 385% |

| Compression Set | 25% |

| Tear Strength | 45 N/mm |

| Specific Gravity | 1.23 g/cm³ |