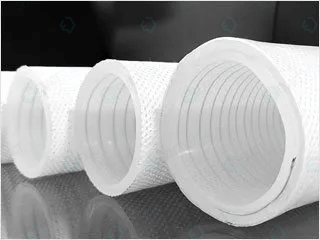

Food and Pharma Hose

Key Features

| Reinforced silicone material |

| Great flexibility |

| Minimum bend radius |

| Stringent manufacturing parameters |

| PTFE lining option |

| FDA and USP Class VI compliant |

| Customizable design |

Expert Manufacturing of Food and Pharma Hose

Exactseal is a leading manufacturer of high-quality Food and Pharma Hose that meets the highest standards of hygiene and performance in the food and pharmaceutical industry. Our hoses are made from food-grade rubber that is approved for contact with food, such as milk, water, air, chemicals, or powders. It is also resistant to abrasion, chemicals, and temperatures, and has good flexibility and hygiene. At Exactseal, we specialize in producing high-quality food and pharma hoses. Our range includes platinum cured silicone tubing, pharmaceutical tubing (pharma tubing), and hoses compliant with USP Class 6 standards. Each product is crafted using advanced techniques and top-grade materials to ensure safety and compliance in food and pharmaceutical applications.

Versatile Uses in Food and Pharma Industries

Our food and pharma hoses are essential for various applications in the food and pharmaceutical industries. Platinum cured silicone tubing ensures safe and hygienic transfer of food and pharmaceutical products. Pharma tubing and pharmaceutical tubing meet stringent industry standards for purity and compatibility with medical and pharmaceutical substances. Our products maintain product integrity and ensure compliance with regulatory requirements.

Designed for Safety and Compliance

At Exactseal, we prioritize safety and compliance in our products. Our platinum cured silicone tubing and pharma tubing meet the highest standards of cleanliness and purity. We use high quality materials that are resistant to wear, extreme temperatures, and chemicals, ensuring reliable performance and long-term durability. Whether you need a hose for food processing or pharmaceutical applications, our products deliver consistent quality and safety.

Customized Solutions for Specific Needs

Understanding the unique requirements of the food and pharmaceutical industries, we offer customized solutions for food and pharma hoses. Our hoses are available in various sizes, lengths, and colors to suit your specific needs and preferences. Whether you need hose for dairy, beverage, or cosmetic products, or for pneumatic, powder, or granule conveying, we have the perfect solution for you. Our team collaborates closely with clients to design and manufacture hoses that meet specific regulatory and operational needs. Whether you need a particular size, configuration, or material, we can create the perfect hose for your application. Our custom solutions ensure optimal performance and satisfaction for your specific requirements.

Commitment to Quality and Service

Quality is fundamental to everything we do at Exactseal. We adhere to rigorous quality control processes to ensure every food and pharma hose meets our high standards. We use advanced technology and equipment to ensure the quality and consistency of our products. We also follow strict quality control and testing procedures to ensure the safety and reliability of our hose. We are certified by ISO 9001:2015 and FDA, and we comply with all the relevant standards and regulations in the food and pharmaceutical industry. Our dedication to using the best materials and manufacturing techniques guarantees superior performance and reliability. Choose Exactseal for your food and pharma hose needs and experience the difference in quality and service. Trust us for all your platinum cured silicone tubing, pharma tubing, pharmaceutical tubing, and USP Class 6 compliant hose requirements, and discover why we are a trusted partner in food and pharmaceutical solutions.

Specification

| Application | Delivery of food, beverage, and pharmaceutical products, such as milk, water, air, chemicals, or powders. |

| Product | Food/Pharma Hose |

| Hardness (Shore A) | 50-60 |

| Material | Silicone, Silicone Sponge, EPDM, EPDM Sponge, Nitrile (Buna N), FKM (Viton), Neoprene, TPV (Santoprene), TPE |

| Colour | We can craft in almost any colour |

Applications

| Dairy, beverage, and cosmetic products |

| Pneumatic, powder, or granule conveying |

| Water, air, or fuel conveying |

| Food factory venting |

| Cereal manufacturing |

| Pharmaceutical manufacturing |

| Sugar, flour, and spices manufacturing |

Technical Information

| Property | Value |

|---|---|

| Compound | Silicone rubber |

| Density [Specific Gravity] | 1.1 to 1.2 |

| Tensile Strength | 5.5 to 11 MPa |

| Elongation at Break | 200 to 500% |

| Minimum Temperature | -60°C [-76°F] |

| Maximum Temperature | 200°C [392°F] |