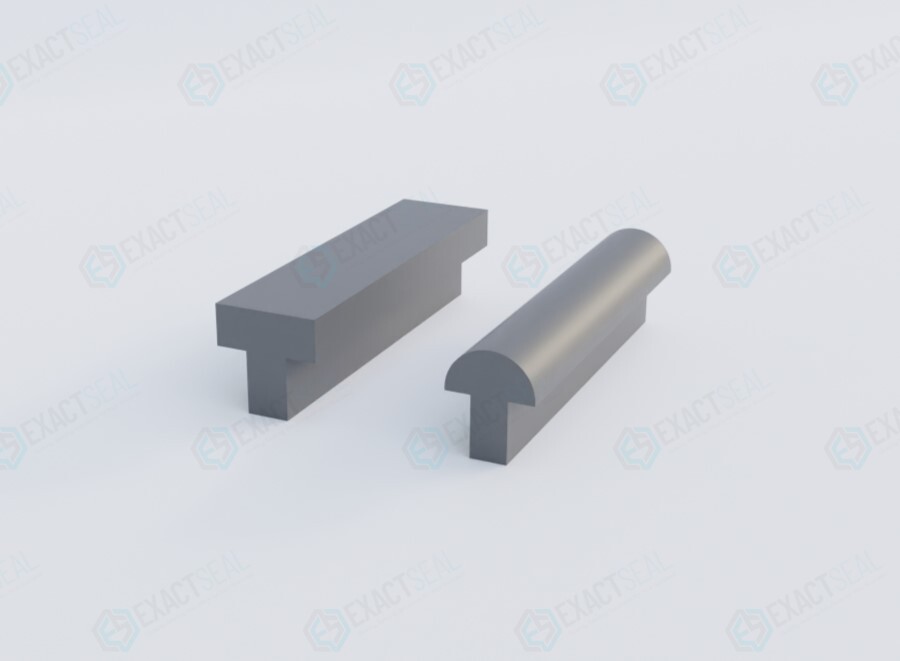

Silicone Rubber Molded Parts

Key Features

| High Temperature Resistance |

| Excellent Flexibility and Durability |

| Superior Electrical Insulation |

| Good Chemical Resistance |

| Outstanding Weatherability |

| Low Compression Set |

| Broad Hardness Range |

Introduction to Silicone Rubber Molded Parts

At Exactseal, we specialize in manufacturing high-quality silicone rubber molded parts, designed to meet a variety of industrial and commercial needs. Our expertise in liquid silicone molding and silicone rubber injection molding ensures that we deliver products of exceptional quality and precision. As leading silicone molding manufacturers, we pride ourselves on our ability to provide reliable and efficient solutions for all your silicone molding requirements.

Versatile Applications Across Industries

Silicone rubber molded parts from Exactseal are used in a wide range of industries due to their versatility and durability. Our parts are ideal for applications in the automotive, medical, aerospace, and consumer goods sectors. Whether it’s for creating seals, gaskets, or custom components, our liquid silicone molding and silicone rubber injection molding processes ensure that each part meets the highest standards of performance and reliability.

Advanced Manufacturing for Superior Performance

Our silicone rubber molded parts are engineered using advanced manufacturing techniques to ensure optimal performance and longevity. The liquid silicone molding process allows for the production of complex and detailed parts with high precision. Silicone rubber injection molding is perfect for creating high-volume, consistent parts that maintain their properties under extreme conditions. These methods ensure that our silicone rubber molded parts offer excellent resistance to temperature, chemicals, and mechanical stress.

Custom Solutions to Meet Your Needs

Exactseal understands that each application has unique requirements. We offer custom silicone rubber molded parts tailored to your specific needs. Our team works closely with clients to design and manufacture parts that meet precise specifications. Whether you need a particular shape, size, or material composition, we can create the perfect solution for your application. Our custom liquid silicone molding and silicone rubber injection molding services ensure that you receive parts that deliver optimal performance and satisfaction.

Commitment to Quality and Customer Satisfaction

At Exactseal, quality is our top priority. We follow stringent quality control processes to ensure that every silicone rubber molded part meets our rigorous standards. Our commitment to using high-grade materials and cutting-edge manufacturing techniques guarantees superior performance and reliability. By choosing Exactseal, you are assured of top-quality silicone rubber molded parts, manufactured to meet your exact requirements. Trust us for all your liquid silicone molding, silicone rubber injection molding, and custom silicone molding needs. Experience the difference in quality and service with Exactseal, your trusted partner for high-performance silicone rubber molded parts.

Specifications

| Application | Various industrial applications such as automotive, electronics, medical devices, etc. |

| Product Name | Silicone Rubber Molded Parts |

| Hardness (Shore A) | Typically ranging from 20 to 80 |

| Material | 3-A Sanitary Grade Silicone, Food & Medical Grade (FDA 21, CFR177.2600 compliant), FDA Grade Closed Cell Silicone Sponge, NSF/ANSI 51 Approved, USP CL-VI Approved, UL-94 Compliant Silicone, Fire Retardant Silicone, Weather Resistant Silicone, X-Ray detectable, Thermally Conductive Silicone (Galss loaded), Electrically Conductive Silicone (Carbon loaded), Mil-Spec AA 59588, Petrochemical Resistant Fluorosilicone |

| Colour | Customizable, Available in a wide range of colors. |

Applications

| Sealing Solutions in Automotive Industry |

| Medical Devices and Health Care |

| Home Appliances Sealing Applications |

| Electronics and Electrical Insulation |

| Aerospace and Aviation Components |

| Industrial Machinery and Equipment |

Technical Information

| Property | Value |

|---|---|

| Material | Silicone Rubber |

| Hardness (Shore A) | 20-80 |

| Tensile Strength | 7-12 MPa |

| Elongation at Break | 300-700% |

| Tear Strength | 15-30 kN/m |

| Compression Set | <20% |

| Temperature Range | -60°C to +200°C |