Rubber Tubing Extrusion

Key Features

| Flexibility and Elasticity |

| Chemical, Weather, Temperature, Abrasion Resistance |

| Customization Options |

| High Quality Material |

| FDA Standards Approved |

| Range of diameters available |

| Easy to cut to size |

Rubber Tubing Extrusion Excellence

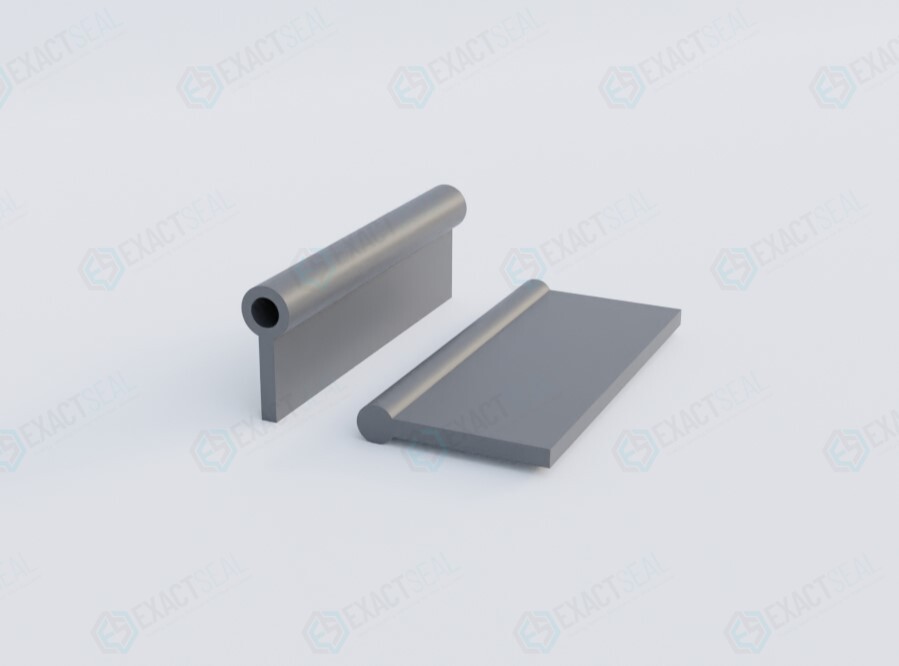

At Exactseal, we specialize in the manufacturing of custom rubber extrusions, with an additional capability to produce extrusions in PVC. Our rubber tubing extrusion is versatile, finding common applications in sealing, noise control, vibration management, and decorative trim. With a comprehensive product range and an extensive library of over 5000 dies, we cater to diverse needs, ensuring a solution for every application. Some of our rubber tubing products are EPDM tubing, Viton tubing, Silicone tubing, etc. We also offer rubber hose in these materials like Viton hose, Viton hose, NBR hose, etc. As a custom rubber extrusion manufacturer, we strive to manufacture tubing and hose as per your requirements.

Comprehensive Extrusion Services

Our commitment to excellence extends to offering a complete extrusion design service, tailored to fit any application. Moreover, we provide post or in-fabrication services, including cutting, drilling, punching, notching, and slotting. Whether it’s a simple cord, rectangle, or a complex co-extruded product with die cutting, Exactseal is well-equipped to assist you.

Customized Compounds for Unique Needs

Understanding the uniqueness of each application, we offer customization of compounds. Our standard rubber extrusions feature weather-resistant EPDM or SBR elastomers. However, for specialized requirements, we provide extrusions in Silicone, Coloured EPDM, Nitrile, and Plastic. For applications demanding higher performance, options like Neoprene, Viton*, and Buna N are available.

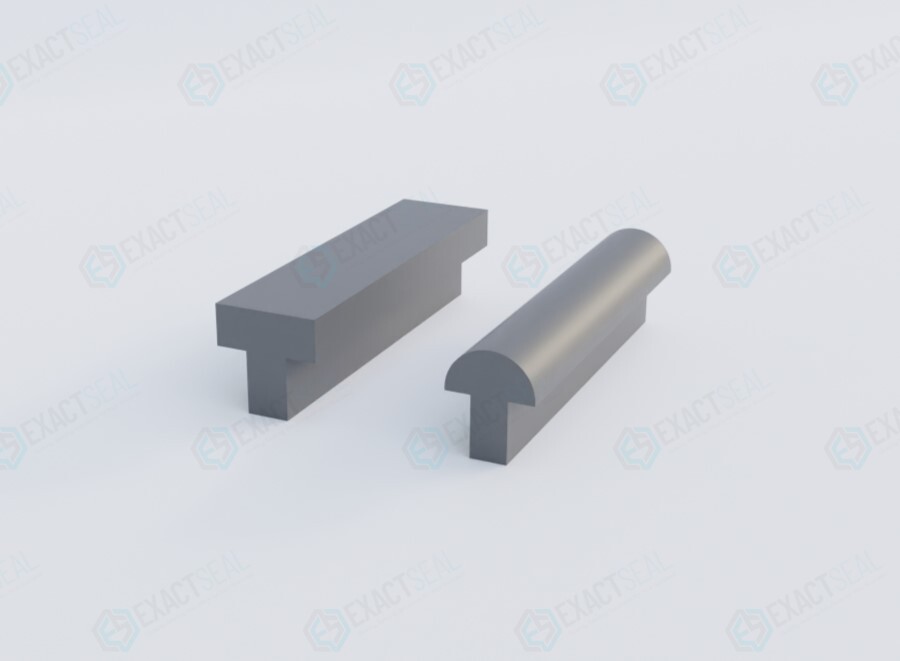

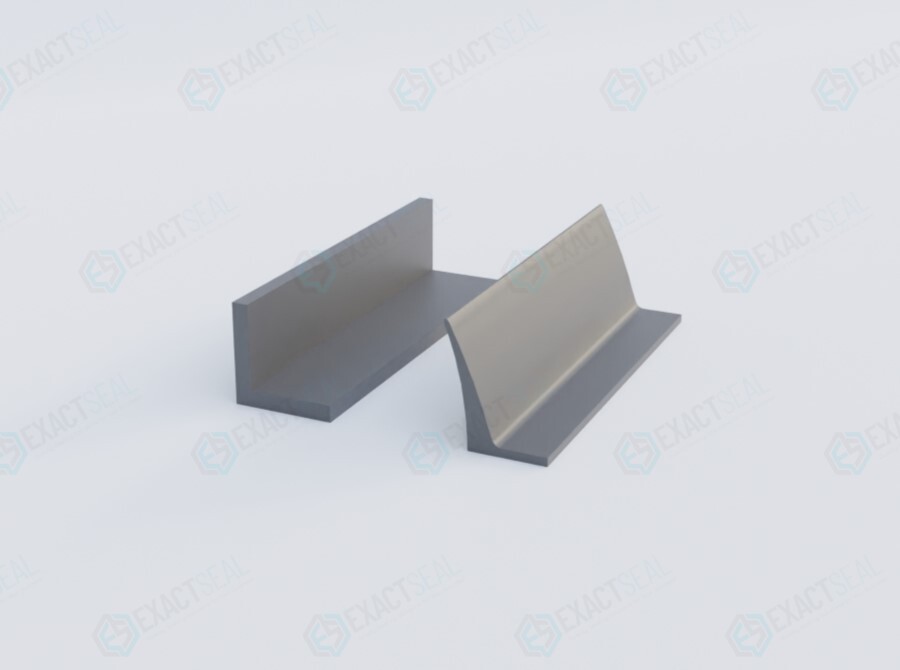

Diverse Product Range

Our tubing extrusion product range includes U-Channel Extrusions, Extruded Rubber Tubing, Seals, Extruded Rubber Profiles, Dual-Durometer Extrusions, Closed Cell Sponge, Continuous Sheet for die-cutting applications, Flame Retardant Neoprene and Silicone, Energy Saving EPDM Weather Seals, Fluroelastomer Extrusions, Coatings, Conductive Extrusions and Coatings, Miniature Profiles, Colour Matching, Contact Adhesives, Self-Lubricating Silicone, EPDM Tubing, Rubber Hose, Viton Hose, Viton Tubing, NBR Hose, and Injection and Transfer Molded products. Adhesives are also available upon request.

Industries We Serve

Exactseal proudly serves various industries, including Marine, Construction, Engineering, Automotive, Shop Fitting, Office Partitioning, Packaging, Lighting, Medical Products, DIY, Furniture, Domestic Appliances, and other manufacturing sectors.

Tailored Solutions with Prompt Service

Our dedicated team of rubber experts strives to provide cost-competitive rubber tubing that meet customers’ exacting needs, ensuring a short lead time from initial design through to production. If you require something not listed here, feel free to contact us via phone or our online form. At Exactseal, your unique requirements are our priority.

Specifications

| Product | Silicone Rubber Tubing | Neoprene Rubber Tubing | Natural Rubber Tubing |

| Application | Culinary, Healthcare, Pharma, Peristaltic pumps, Dairy pump applications, RC car fuel lines, Machinery production. | General purpose, Schools, Laboratories, Gas/Water taps | Scientific labs, Water/gas faucets, Condenser columns, Bunsen burners, Gas and liquid transfers, Diluted acid handling. |

| Hardness (Shore A) | 20° - 80° | 69° | 45° |

| Material | Silicone | Neoprene | Natural Rubber |

| Colour | Translucent as standard (other colours available) | Black | Red |

Applications

| Applications involving food and beverages |

| Pharmaceutical sectors |

| Utilized in peristaltic pumps |

| Dairy pump applications |

| Fuel tubes for RC model cars |

| Used by industrial manufacturers |

| Faucets for water |

| Gas transfer |

| Transfer of liquids and diluted acids |

| Educational institutions |

| Lab environments |

| Outdoor settings |

| Versatile general applications |

Technical Information

| Property | VALUES | ||

|---|---|---|---|

| Compound | Silicone | CR | NR |

| Specific Gravity | 1.15g/cm³ | 1.40g/cm³ | 1.22g/cm³ |

| Tensile Strength | 10.3N/mm² | 8.77 MPa | - |

| Elongation at Break | 600% | 255.45% | - |

| Minimum Temperature | -40°C | -40°C | -65°C |

| Maximum Temperature | 200°C | 125°C | 70°C |