Key Features

| Versatile product with high compression rates |

| Noteworthy "shape memory" properties |

| Wide operational temperature range |

| Effective UV, weathering, and ozone resistance |

| Excellent flexibility |

| Efficient and straightforward installation |

| Available in multiple sizes from stock |

| Customized manufacturing options offered |

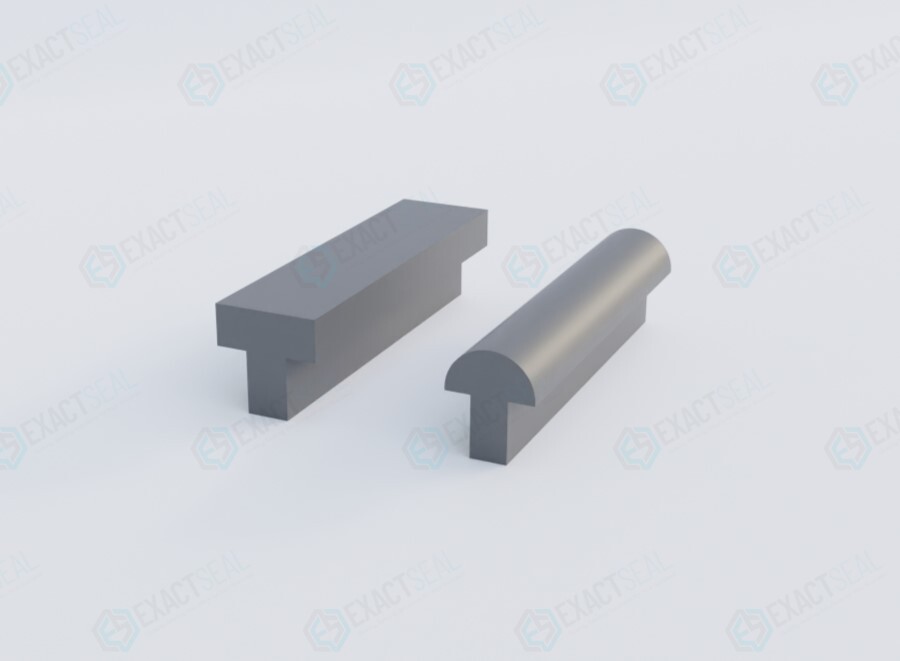

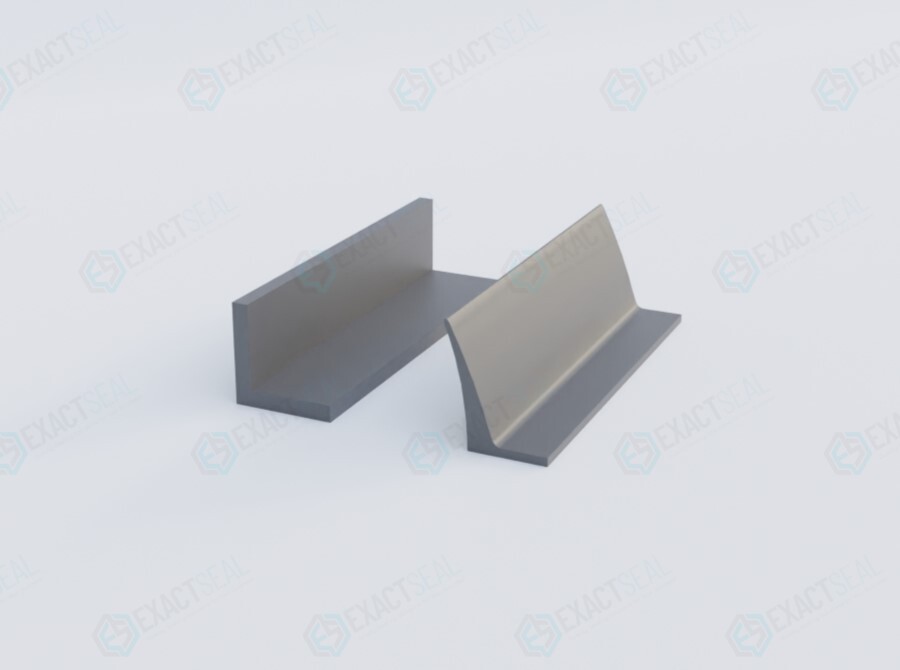

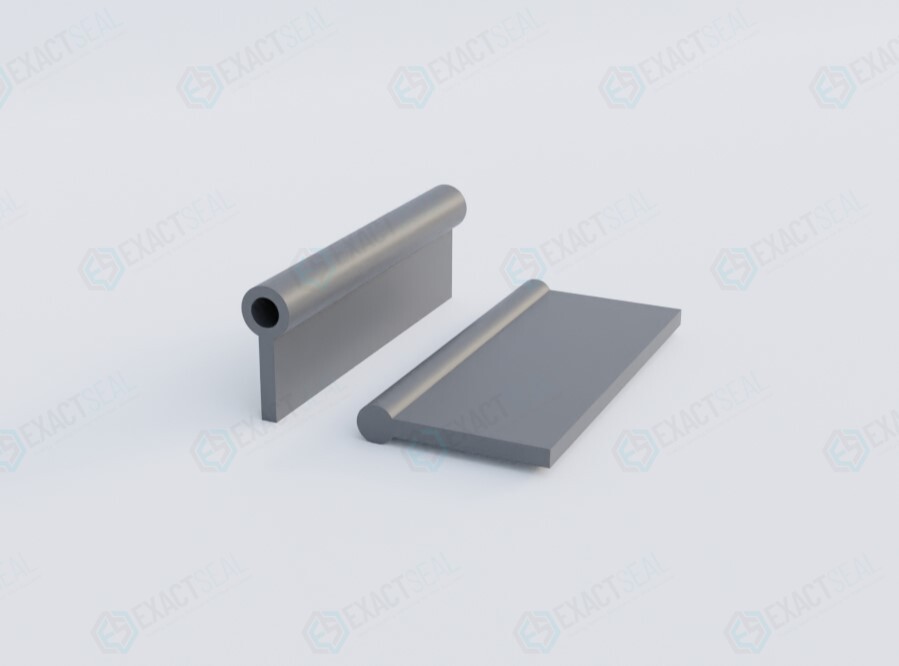

Presenting our exceptional P Seal Profile. It is a highly versatile and widely recognized rubber extrusion known by various names such as P seal, piping extrusion, bead profile, tadpole seal, P Shaped Rubber Seal, P Gasket, and music note seals. This profile offers unparalleled sealing performance and is utilized across diverse industries for its reliability and effectiveness. Crafted from high-quality materials including EPDM, silicone, and rubber TPE, our P seal come in diverse bead and flange sizes, ensuring a perfect match for your specific requirements. Whether you need silicone P seal, EPDM P seal, NBR P seal or Customized Rubber Extrusion, Exactseal is one stop solution. As a leading custom rubber extrusion manufacturer, we provide Extruded Rubber Bumper or any kind of other rubber extrusion parts upon your requirements.

Versatile Performance: P Seal Profile, highly versatile and commonly used in both industrial and private applications, offers excellent sealing and protective properties. Available in both hollow and solid forms, these profiles cater to a wide range of applications.

Our P Shaped Rubber Seals comes in

- Rubber TPE: Thermoplastic elastomers (TPE) combine rubber and plastic polymers, providing superior “shape memory” ideal for sealing applications. TPE P shaped seal exhibit a wide temperature range, making them suitable for various environments.

- Silicone: Silicone rubber, prized for non-reactivity and extreme temperature resistance (-50°C to 300°C), is perfect for outdoor and food contact applications. Our FDA-approved silicone P seal ensure safety in food-related uses, being non-leaching and pyrogen-free.

- EPDM: Rubber EPDM, with its closed-cell structure, excels in sealing out water and enduring various weather conditions. Noteworthy chemical resistance makes it perfect for sealing applications, especially in vehicle seals. Additionally, it’s lightweight and easy to cut for convenience.

- Neoprene: Offering superior degradation resistance, Neoprene stands out in demanding applications with excellent fire and burn resistance. Despite a narrower temperature range (-6°C to 93°C), Neoprene maintains good chemical stability and flexibility. P gaskets made of neoprene can be used in challenging environments.

We manufacture customized rubber extrusion

We offer more than just Silicone, EPDM, Neoprene, and TPE. Our expertise extends to crafting P-shaped seals and various other rubber profiles tailored to your requirements. Reach out to us for a complimentary quote. Our skilled team is ready to support you with all your rubber sealing requirements.

Specifications

| Application | Sealing & decorative trim in various industrial & marine industries |

| Product | P Seal Profile |

| Hardness (Shore A) | Contact us for specific profiles |

| Material | Silicone, EPDM, Neoprene, Nitrile (Buna-N), FKM (Viton), FFKM (Kalrez), TPE, TPV |

| Colour | Varies based on Material Selection |

Applications

| General purpose |

| Door seals |

| Window seals |

| Hatch seals |

| Cable protection |

| Vehicle panel piping |

| Interior & exterior applications |

Technical Information

| Properties | Values |

|---|---|

| Compound | TPE / Silicone / EPDM / Neoprene |

| Minimum Temperature | -40°C / -50°C / -40°C / -6°C |

| Maximum Temperature | +250°C / +300°C / +93°C / +93°C |

| Compression Set Resistance | Excellent / Superior / High / High |

| Chemical Resistance | Moderate / Excellent / High / High |

| UV Resistance | Excellent / Exceptional / High / High |

| Tensile Strength | Good / Superior / Excellent / High |