Metal Detectable Silicone Gasket

Key Features

| Detectable by Metal Detectors |

| High Temperature Resistance |

| Excellent Chemical Resistance |

| Superior Durability and Flexibility |

| Food Grade Compliance |

| Customizable Sizes and Shapes |

| Wide Industrial Application |

Exactseal offers high-quality metal detectable silicone gaskets designed to meet the stringent requirements of food and pharmaceutical industries. Our metal detectable silicone gaskets provide reliable sealing solutions while ensuring product safety and regulatory compliance. With their unique metal detectable properties and FDA 21 CFR 177.2600 compliance, our gaskets are ideal for applications where contamination prevention is critical. We make these gaskets from silicone rubber infused with a detectable material. This allows the gaskets to be detected by metal detectors.

Metal Detectable Silicone: Detecting Contaminants With Precision

We specially formulate our silicone with detectable additives that allow for easy identification and removal of gasket fragments in food and pharmaceutical processing lines. With its metal detectable properties, our silicone material enhances product safety and reduces the risk of product contamination. Manufactured to comply with FDA 21 CFR 177.2600 requirements, our metal detectable silicone provides peace of mind in critical applications where food safety is paramount.

Compliance With FDA 21 CFR 177.2600 Standards

Exactseal’s metal detectable silicone gaskets are manufactured to comply with FDA 21 CFR 177.2600 standards, ensuring safety and regulatory compliance in food contact applications. Additionally, we make our gaskets from high-quality silicone rubber materials that meet the strict requirements of FDA regulations. With their FDA compliance and metal detectable properties, our gaskets provide reliable sealing solutions while minimizing the risk of product contamination in food processing and pharmaceutical industries.

We Manufacture Customized Seals & Gaskets

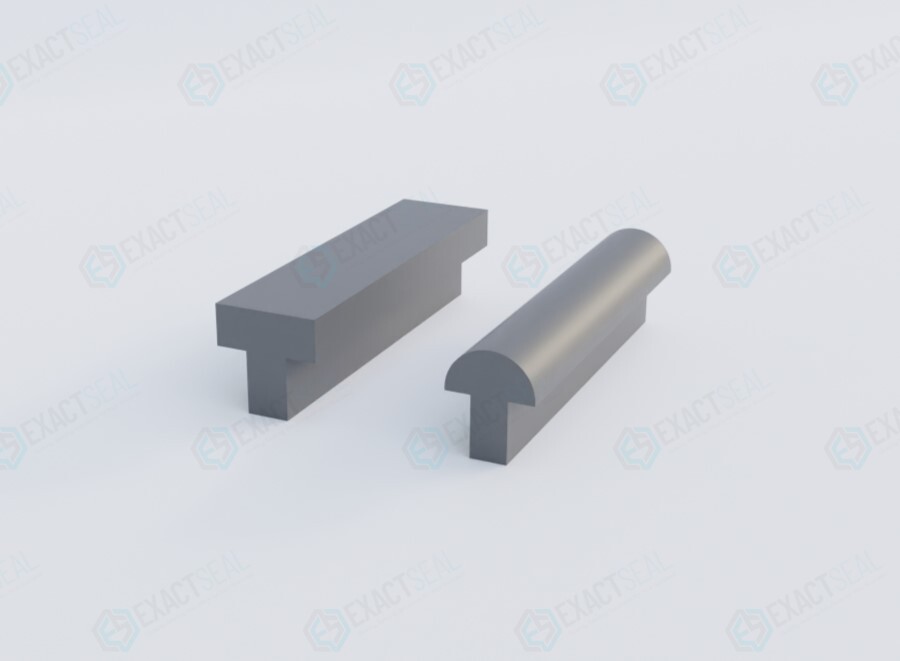

We offer a variety of Metal Detectable Silicone Gaskets, each custom-made to fit the specific requirements of our clients. Our experienced team work closely with our customers to understand their needs and provide solutions that are both practical and efficient.

At Exactseal, we are committed to providing our clients with top-notch products and services. Our team of experts is always ready to assist you in choosing the right Metal Detectable Silicone Gasket for your needs. Moreover, we also offer custom design services to ensure that the gaskets you receive are perfect for your application.

Why Choose Exactseal For Metal Detectable Silicone Gaskets?

We take pride in our ability to deliver high-quality products on time and within budget. Our dedication to customer satisfaction is what sets us apart in the industry. When you choose Exactseal, you’re choosing a partner who values your business and works tirelessly to meet your needs.

Safety and Compliance: Our metal detectable silicone gaskets meet FDA 21 CFR 177.2600 standards. Therefore, this ensures safety and regulatory compliance in food contact applications.

Enhanced Product Safety: With their metal detectable properties, our gaskets allow for easy identification and removal of fragments. This enhances product safety and reduces the risk of contamination.

Reliable Sealing Solutions: Our metal detectable silicone gaskets provide reliable sealing solutions for food and pharmaceutical processing lines. They ensure product integrity and quality.

Expertise and Support: With years of experience in silicone rubber extrusion, our team provides expert advice and support. This helps you find the right sealing solution for your specific application.

Specifications

| Application | Various Industries |

| Product Name | Metal Detectable Silicone Gasket |

| Hardness (Shore A) | 20-80 |

| Material | Silicone, EPDM, Nitrile (Buna-N), FKM (Viton), Neoprene, TPE, TPV (Santoprene), HNBR, SBR, PTFE (Teflon), FFKM (Kalrez), Natural Rubber |

| Colour | Customizable |

Applications

| Food and Beverage Processing |

| Pharmaceutical Manufacturing Equipment |

| Dairy Industry Machinery |

| Cosmetic Production Lines |

| Chemical Processing Plants |

| Water Treatment Facilities |

Technical Information

| Property | Value |

|---|---|

| Material | Metal Detectable Silicone |

| Hardness (Shore A) | 20-80 |

| Tensile Strength | 7-12 MPa |

| Elongation at Break | 300-700% |

| Tear Strength | 15-30 kN/m |

| Compression Set | <20% |

| Temperature Range | -60°C to +200°C |