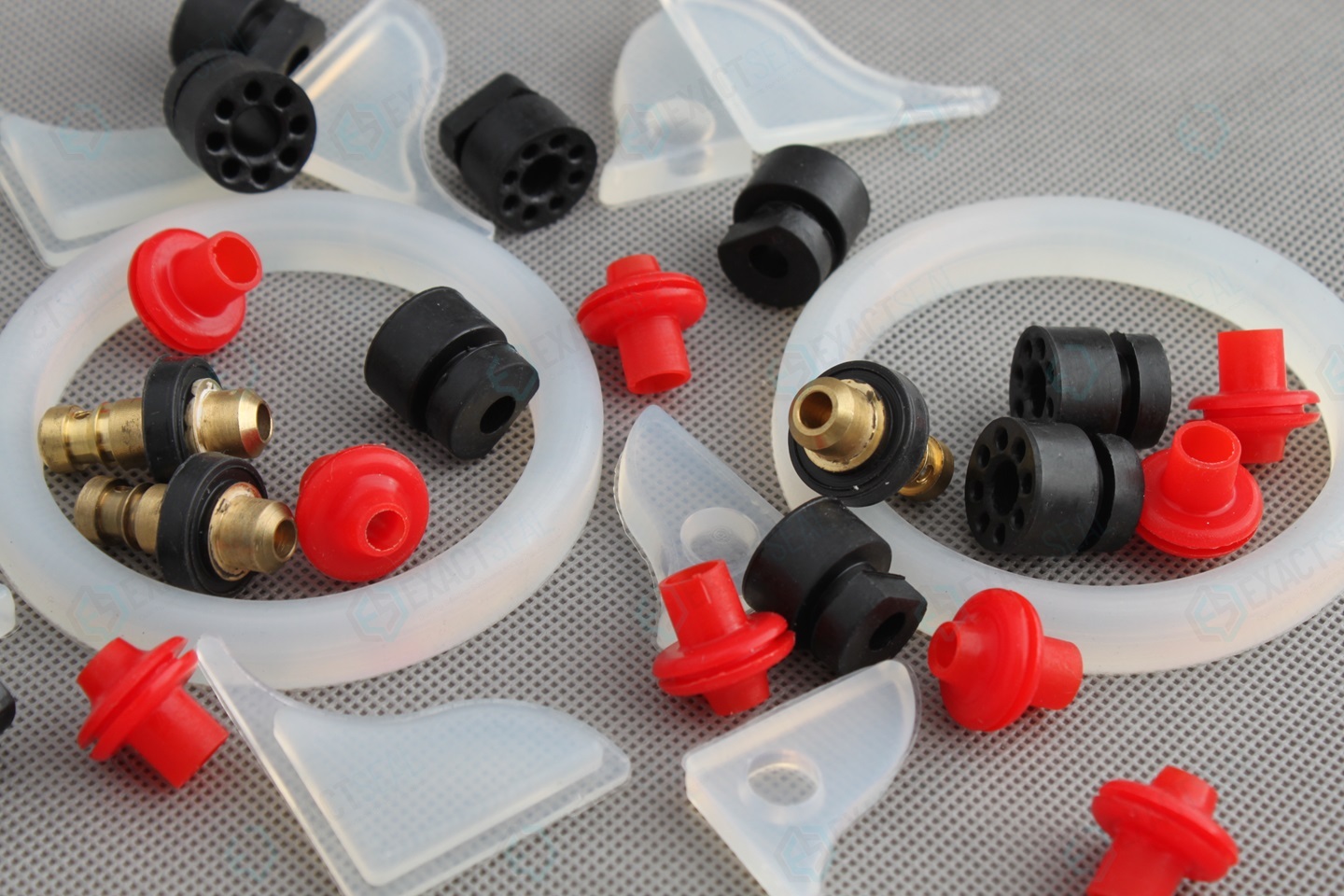

Custom Rubber Molded Parts

At Exactseal, our dedication to precision engineering, constant focus on quality, and experience in a wide range of elastomer materials are evident in our capability to manufacture a variety of molded rubber products. With a commitment to manufacturing excellence, we specialize in compounding and manufacturing molded rubber components that cater to a diverse range of industries and applications.

Molded Rubber Products: Our expertise in molded rubber products spans a wide spectrum of capabilities, delivering custom rubber components that meet the unique needs of various industries. Our molded rubber products showcase precision in design and manufacturing, providing reliable performance and durability. From intricate designs to critical applications, our molded rubber components serve as integral parts across diverse sectors.

Materials and Customization:

The manufacturing of molded rubber products involves the use of high-quality rubber compounds, carefully selected to match the specific requirements of each application. Our customization capabilities ensure that the material composition, hardness, and design precisely align with the intended use. Whether it’s for automotive, aerospace, medical, or industrial applications, our molded rubber products are tailored to meet industry standards and client specifications. We specialize in molding variety of rubber components:

- Silicone: High-temperature resistance, biocompatibility, and flame retardancy. Used in medical devices, food-grade applications, and high-heat environments.

- EPDM, TPV (Santoprene): Excellent weather resistance and ozone resistance. Popular in outdoor applications like roofing membranes and automotive parts.

- Polyurethane: Offers a wide range of properties depending on formulation. Used in tires, footwear, and vibration dampeners.

- Natural Rubber: Offers excellent elasticity, resilience, and abrasion resistance. Widely used in tires, hoses, and seals.

- Neoprene: Known for its oil and chemical resistance, making it ideal for gaskets, seals, and fuel lines.

- Nitrile, FKM(Viton), FFKM(Kalrez, Tecnoflon): Strong resistance to oils, fuels, and solvents. Popular for O-rings, seals, and hoses in demanding environments.

Molding Processes:

- Compression Molding: A versatile and cost-effective method for high-volume production of simple to complex shapes. Suitable for various materials, including natural rubber, neoprene, and EPDM.

- Transfer Molding: Offers faster cycles and tighter tolerances compared to compression molding. Ideal for intricate parts, especially with metal inserts or over molding.

- Injection Molding: High-speed, automated process for consistent, high-volume production of precise parts. Often used for thermoplastics, but some companies specialize in injection-molded rubber, particularly silicone.

Versatility in applications:

At Exactseal Inc., our molded rubber products are designed to excel across a wide range of industries. Our precision-engineered rubber grommets and molded rubber O-rings enhance automotive components and industrial machinery with superior sealing and performance. For more specialized needs, our rubber quad rings offer exceptional sealing capabilities, while our inflatable actuators deliver versatile and reliable functionality in various applications. Additionally, our nitrile oil seals and rubber bellows are engineered to withstand harsh conditions, ensuring durability and optimal performance in demanding environments.

We prioritize quality assurance in every step of our manufacturing process, with stringent testing to ensure all products meet or exceed industry standards. Our commitment to environmental responsibility is reflected in our use of eco-friendly materials and sustainable practices, aiming to reduce our ecological impact.

Choose Exactseal for molded rubber products that stand for precision, reliability, and versatility. Our dedication to excellence and customization makes us a trusted partner in rubber product manufacturing.